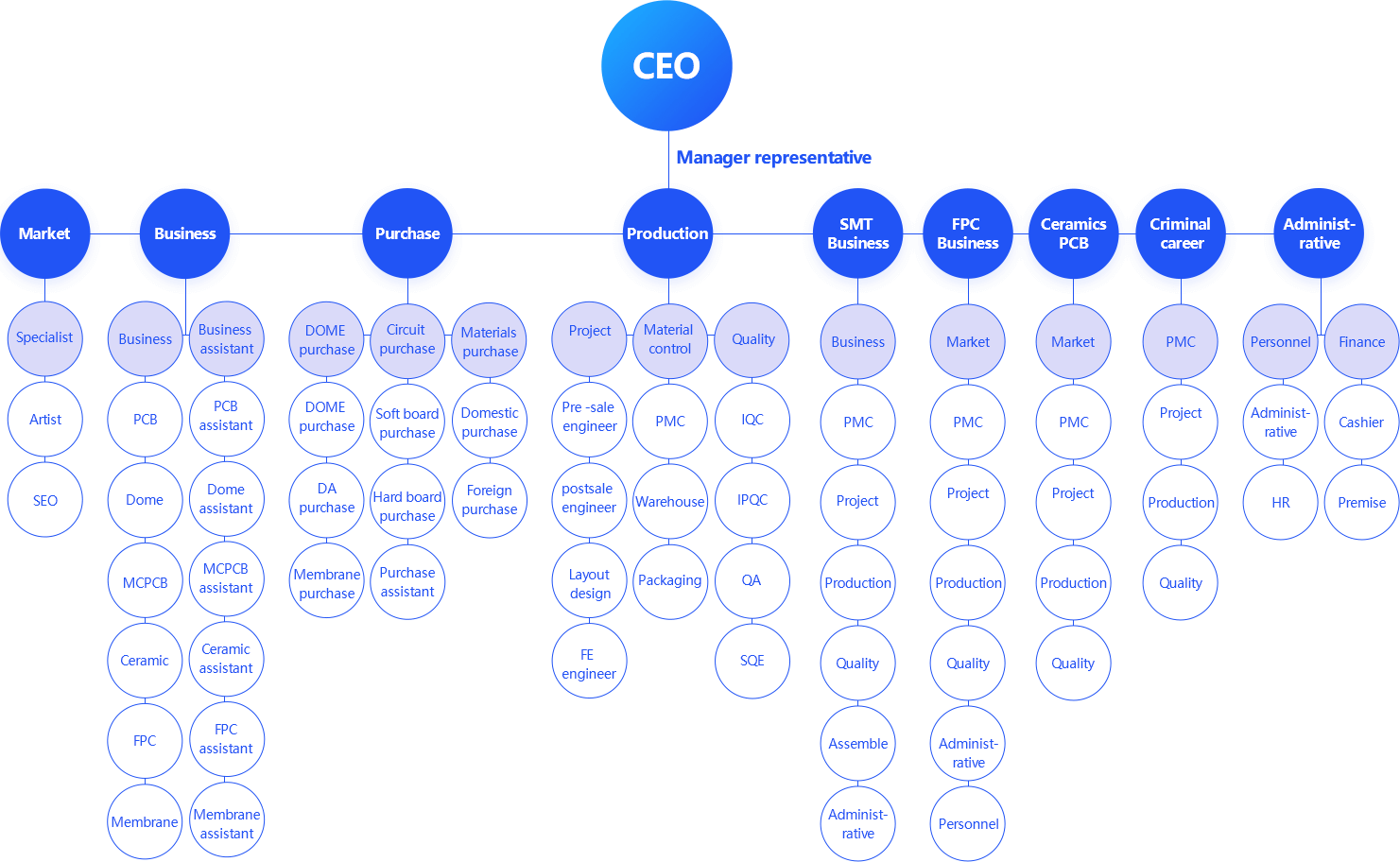

About BSTCeramicPCB Co., LTD

BSTCeramicPCB Co., LTD is located in the industrial core area of circuit board, Shajing Street, Baoan District, Shenzhen City. With a vast network of upstream and downstream circuit board resources, we are well-equipped to provide our customers with prompt and efficient ceramic circuit board and assembly services. Since its establishment, BSTCeramicPCB committed to becoming the most reliable, high-quality ceramic PCB and PCBA one-stop solution fast provider.

Fast response is what we focus on

BSTCeramicPCB is mainly engaged in designing and manufacturing ceramic circuit boards, including various technology such as DPC ceramic PCB, DBC/DCB ceramic circuit, AMB ceramic PCB and LTCC ceramic PCB. We have a full series of high-tech equipment to make sure rapid production, good quality, high output, short lead-time and fast delivery.

Focusing on medical equipment, automotive electronics, frequency conversion braking, instrumentation, power supply, industrial control, radar communication, national defense and other industries, BSTCeramicPCB provides high-quality ceramic circuits including circuit board assembly and related solutions for our customers. We have a strong R&D team and mature production control process that support us to produce and ship out defective-free and 100% good quality products.

we deliver ceramic substrates(ceramic pcb) depending on the ceramic PCB type..

Once get your approval of FPC prototypes and decision of MP (mass production), the fast LT will be:

1. For Thick Film Ceramic PCB: 3-4 Weeks 4. For DBC Ceramic PCB: 5-6 Weeks 7. For HTCC Ceramic PCB: 4-5 Weeks

2. For Thin Film Ceramic PCB: 4-5 Weeks 5. For AMB Ceramic PCB: 2-2.5 Weeks

3. For DPC Ceramic PCB: 4-5 Weeks 6. For LTCC Ceramic PCB: 3-4 Weeks

All steps what we do are aimed at meeting your requirements.

Three Basic Principles to Achieve Win-Win

No MOQ Limit

Whether it is a start-up company or a brand company, we welcome them equally. Whether it is 1PCS or mass production, we guarantee the quality, quantity and delivery time. The growth of customers is the growth of BSTCeramicPCB! 01

Solving Design Challenges

We have been solving ceramic board design problems for 17 years. Whether it is your own PCB design or design your own PCB, we can provide experience and assistance. Dreams cannot stop at the beginning! 02

Strict Quality Control

The four cores "Raw Material Guarantee, Pre-production Inspection, In Process Quality Control, Rigorous Testing And Inspection" ensure that the quality of ceramic plates exceeds the standard. Continuously improving the quality inspection system is the only way for the company to develop! 032019

2018

2017

2016

2015

2014

2013

2010

2007

2006

2019

2018

2017

2016

2015

2014

2013

2010

2007

2006

Company Culture

Vision: To Be the Most Reliable One-Stop Fast Solution Provider of Electronics and Circuit Board in the World.

Mission: Making Quality Circuit Board & Electronics Chips with Attentive and Innovative Service.

Company Purpose

Core Value: As a member in BEST, our core values prompt us to do everything well and feeling hopeful about the future, also drive a positive and inclusive culture as we strive excellence.

HOME

HOME