Ultra-thin Ceramic Substrate Thin Film PCB For Vehicle Driving Control System

Board Thickness: 1.0mm

Conductor: 0.1umTiW+0.2mm Ni+3.0um Au

Solder Mask: N/A

Silkscreen: N/A

Surface Finishing: N/A

Application: Vehicle Driving Control System

| Item1 | Thin Film Capabilities | Special Needs |

| Circuit layers | 1~2 Layers | N/A |

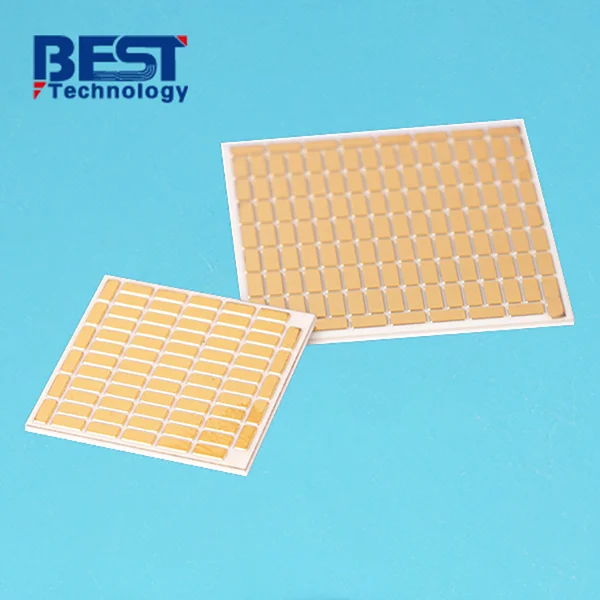

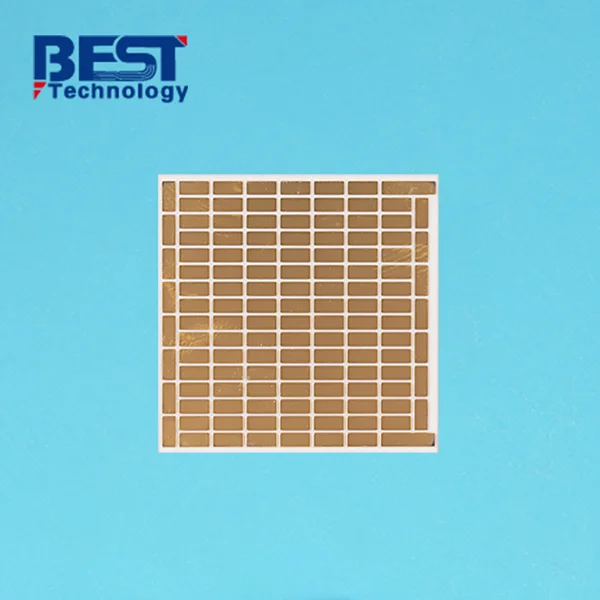

| Product Unit Size | 0.5mmx0.5mm-200mmx200mm | 0.25mmx0.25mm |

| Substrate Thickness Tolerance | ≤ ± 10% | ±0.02mm |

| Element Size Tolerance | ±0.05mm | ±0.03mm |

| Minimum Line Width@Thickness<3μm | 20μm | 10μm |

| Line Width Accuracy | ±5μm | ±2μm |

| Forecast Minimum Size Of Gold-tin Solder | 100μm*100μm | 50μm*50μm |

| Distance From Wire To Substrate Edge | 50μm | min 20μm |

| Minimum Land Size Around Vias | ≥Aperture+50μm | N/A |

| Front, Back, Multilayer Alignment Accuracy | ≤ ± 5μm | ± 1μm |

| Front, Side Alignment Accuracy | ≤ 20μm | N/A |

| Available Cutter Width | 0.1, 0.15, 0.2mm | N/A |

| Cutting Accuracy Of Grinding Wheel | ± 50μm | ± 20μm |

| Laser Cutting Precision | ± 20μm | N/A |

| Minimum Hole Diameter | 0.5*Board Thickness | N/A |

| Aperture Tolerance | ± 10% | N/A |

| Solid Hole Diameter | 0.075, 0.1mm | N/A |

| Item2 | Attributes | Special Needs |

| Brand | BSTCeramicPCB | N/A |

| Substrate type | AlN, Al2O3, Si, Quartz, Glass-ceramic, Diamond, Sapphire | N/A |

| Substrate Roughness (Ra) | ≤0.1μm | ≤0.05μm |

| Coating Type | Metal film, resistive film, dielectric film, functional film, etc. | N/A |

| Film Thickness Tolerance | ±20% | ±5% |

| Resistive film square resistance | 10-200 | N/A |

| Resistance value accuracy (laser trimmable) | ±0.1% | ±0.05% |

| Resistance value accuracy (no laser trimming) | ±5% | ±3% |

| Temperature coefficient of resistance | ±25ppm | min±10ppm |

| Rapid Prototype | Layer | Normal Delivery | Expedited Service |

| Thin Film Ceramic PCB | 1 | 3-3.5 Weeks | 2-2.5 Weeks |

| 2 | 4-6 Weeks | 2-2.5 Weeks |

| Mass Production | Layer | Normal Delivery | Expedited Service |

| Thin Film Ceramic PCB | 1 | 4-5 Weeks | 2-3 Weeks |

| 2 | 4-6 Weeks | 2-3 Weeks |

A thin-film ceramic circuit board is a type of advanced electronic interconnect technology where conductive metal layers are deposited onto a ceramic substrate. This manufacturing process results in compact, lightweight, and highly reliable circuit boards. The use of ceramic material provides superior electrical insulation and excellent heat dissipation properties, making them well-suited for high-power electronic devices and radio frequency applications. Thin-film ceramic circuit boards are favored in the defense and space industries due to their ability to withstand extreme temperature variations and radiation exposure.

Customer background:

AutoTech Automation Solutions Inc. is a leading provider of advanced industrial automation solutions for manufacturing and process industries globally. With expertise in automation engineering, AutoTech delivers high-end control systems, machine vision solutions, and sensors to enhance efficiency and productivity in industrial operations.

Project Requirements:

AutoTech was tasked with developing precision control systems and sensors for a large-scale automation project. The project demanded circuit boards with high-frequency operation and resilience to harsh industrial environments, enabling reliable and efficient automation processes. To meet the requirements for high-frequency operation and withstand extreme temperatures and humidity, AutoTech sought high-performance Thin Film Ceramic PCBs for their precision control systems and sensors. The Thin Film Ceramic PCBs were expected to deliver exceptional electrical performance and reliability in demanding industrial applications.

Project Challenges:

Designing the Thin Film Ceramic PCBs to maintain precise circuitry while withstanding harsh industrial conditions presented a significant challenge. The circuit boards needed to demonstrate high reliability and signal integrity, essential for uninterrupted operation in challenging industrial environments.

Achievements: AutoTech Automation Solutions collaborated with us, and successfully producing circuit boards that passed rigorous testing for performance and reliability finally. The Thin Film Ceramic PCBs demonstrated exceptional resilience in harsh industrial environments, meeting AutoTech's requirements for precision and reliability. The successful deployment of the Thin Film Ceramic PCBs in various automation projects cemented AutoTech's position as a trusted provider of industrial automation solutions.

HOME

HOME