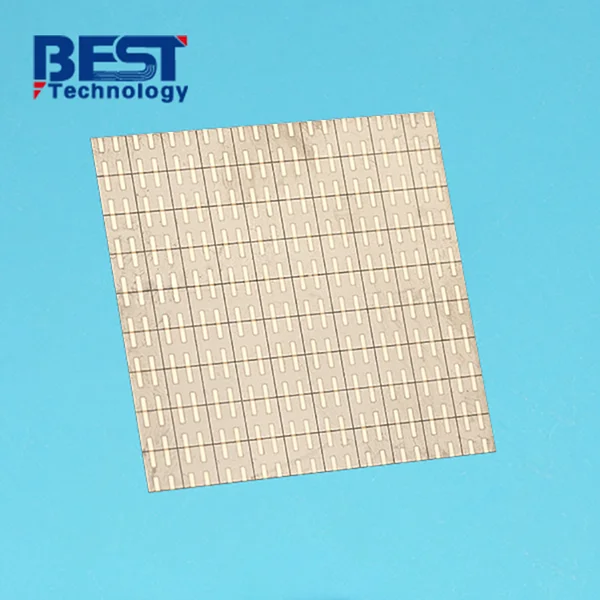

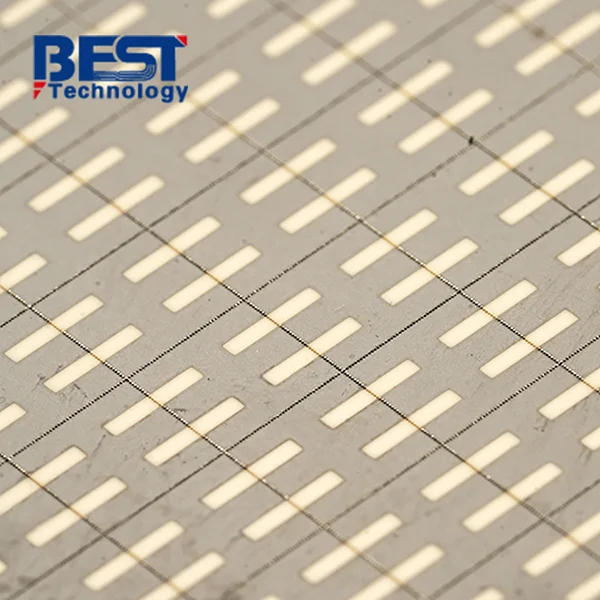

Thin Film Circuit Board Design Production For New Energy System

Board Thickness: 1.0mm

Conductor: 0.1umTiW+0.2mm Ni+3.0um Au

Solder Mask: N/A

Silkscreen: N/A

Surface Finishing: N/A

Application: New Energy System

| Item1 | Thin Film Capabilities | Special Needs |

| Circuit layers | 1~2 Layers | N/A |

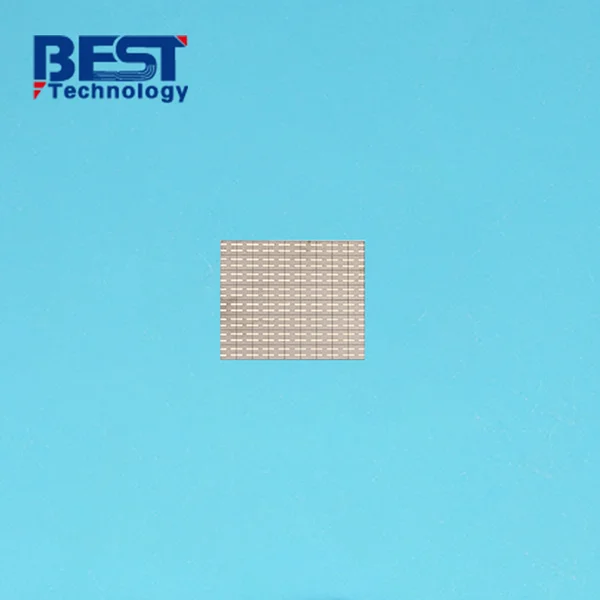

| Product Unit Size | 0.5mmx0.5mm-200mmx200mm | 0.25mmx0.25mm |

| Substrate Thickness Tolerance | ≤ ± 10% | ±0.02mm |

| Element Size Tolerance | ±0.05mm | ±0.03mm |

| Minimum Line Width@Thickness<3μm | 20μm | 10μm |

| Line Width Accuracy | ±5μm | ±2μm |

| Forecast Minimum Size Of Gold-tin Solder | 100μm*100μm | 50μm*50μm |

| Distance From Wire To Substrate Edge | 50μm | min 20μm |

| Minimum Land Size Around Vias | ≥Aperture+50μm | N/A |

| Front, Back, Multilayer Alignment Accuracy | ≤ ± 5μm | ± 1μm |

| Front, Side Alignment Accuracy | ≤ 20μm | N/A |

| Available Cutter Width | 0.1, 0.15, 0.2mm | N/A |

| Cutting Accuracy Of Grinding Wheel | ± 50μm | ± 20μm |

| Laser Cutting Precision | ± 20μm | N/A |

| Minimum Hole Diameter | 0.5*Board Thickness | N/A |

| Aperture Tolerance | ± 10% | N/A |

| Solid Hole Diameter | 0.075, 0.1mm | N/A |

| Item2 | Attributes | Special Needs |

| Brand | BSTCeramicPCB | N/A |

| Substrate type | AlN, Al2O3, Si, Quartz, Glass-ceramic, Diamond, Sapphire | N/A |

| Substrate Roughness (Ra) | ≤0.1μm | ≤0.05μm |

| Coating Type | Metal film, resistive film, dielectric film, functional film, etc. | N/A |

| Film Thickness Tolerance | ±20% | ±5% |

| Resistive film square resistance | 10-200 | N/A |

| Resistance value accuracy (laser trimmable) | ±0.1% | ±0.05% |

| Resistance value accuracy (no laser trimming) | ±5% | ±3% |

| Temperature coefficient of resistance | ±25ppm | min±10ppm |

| Rapid Prototype | Layer | Normal Delivery | Expedited Service |

| Thin Film Ceramic PCB | 1 | 3-4.5 Weeks | 2-2.5 Weeks |

| 2 | 4-6 Weeks | 2-2.5 Weeks |

| Mass Production | Layer | Normal Delivery | Expedited Service |

| Thin Film Ceramic PCB | 1 | 4-5 Weeks | 2-3 Weeks |

| 2 | 4-6 Weeks | 2-3 Weeks |

Thin-film ceramic circuit boards are specialized electronic substrates made from ceramic materials using thin-film deposition techniques. These boards offer exceptional high-temperature stability, making them ideal for applications in industries such as aerospace, automotive, and telecommunications. The thin-film technology allows for precise circuitry patterns, enabling higher circuit density and improved signal integrity. With excellent resistance to thermal and mechanical stresses, these boards provide long-term reliability in harsh operating environments, making them suitable for mission-critical electronic systems.

Customer background:

RenewEco Energy Solutions Inc. is a prominent renewable energy company focused on solar inverters and energy conversion systems. With a commitment to sustainable energy solutions, RenewEco aims to drive the global adoption of renewable energy technologies.

Project Requirements:

RenewEco sought to enhance the efficiency of their solar inverters for maximizing energy conversion. The project required circuit boards with high thermal conductivity for efficient heat dissipation during energy conversion processes. To meet the demands for superior thermal conductivity, RenewEco required high-performance Thin Film Ceramic PCBs for their solar inverters. The Thin Film Ceramic PCBs were expected to efficiently dissipate heat during energy conversion, ensuring optimal performance and longevity of the solar inverters.

Project Challenges:

The Thin Film Ceramic PCB had to achieve superior thermal conductivity while maintaining precise circuitry for efficient power conversion. The challenge was to design a board that could handle high-power loads while remaining stable and reliable.

Post-Project Outcome:

RenewEco Energy Solutions was highly satisfied with the superior thermal performance of the Thin Film Ceramic PCBs. The successful implementation of the circuit boards in their solar inverters resulted in increased efficiency and enhanced energy generation. The partnership with the Thin Film Ceramic PCB manufacturer allowed RenewEco to expand its range of green energy solutions, attracting new customers seeking sustainable and high-performance energy conversion systems.

HOME

HOME