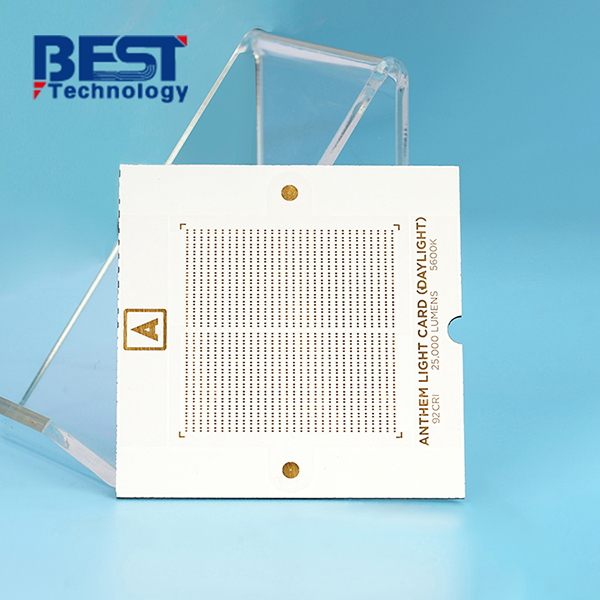

Alumina DPC Ceramic Substrate PCB Design Manufacturing For LED

Board thickness: 1.0mm+/-0.1mm

Conductor: 18um copper

Solder mask: White

Silkscreen: N/A

Surface finishing: ENEPIG 3u’’

Application: LED chip

| Item1 | DPC Capabilities | |||||

|---|---|---|---|---|---|---|

|

Layer Count |

1-2 Layers |

|||||

|

Max Board Dimension |

120mmx180mm | |||||

|

Min Board Thickness |

0.15mm |

|||||

|

Max Board Thickness |

6.0mm |

|||||

|

Conductor Thickness |

50/50μm |

|||||

|

Min Line Width/Line Space |

3/3mil (0.075/0.075mm) |

|||||

|

Substrate Type |

AI2O3, ALN, Si3N4 |

|||||

|

Substrate Thickness |

0.15-6mm |

|||||

|

Min Hole Diameter |

100μm |

|||||

|

Min Hole Spacing |

250μm |

|||||

|

Min PAD Ring(Single) |

0.125mm |

|||||

|

PTH Wall Thickness |

8um |

|||||

|

Min Solder PAD Dia |

0.25mm |

|||||

|

Min Soldermask Bridge |

Green Oil 130μm; Others 150μm |

|||||

|

Min BAG PAD Margin |

0.3mm |

|||||

|

PTH/NPTH Dia Tolerance |

0.05/0.075mm |

|||||

|

Hole Position Deviation |

50-75μm |

|||||

|

Outline Tolerance |

Laser: +/-0.13mm |

|||||

|

Line Width/Spac Tolerance |

±20% |

|||||

|

Surface Treatment |

OSP/Immersion Gold/Nickel Plated Gold/Immersion Silver/Nickel Plated |

|||||

|

Thermal Stress |

7.3pmm/k |

|||||

| Item2 | Attribute | ||

|---|---|---|---|

|

Brand |

CeramTec / GTT / Huaqing / Laird / Maruwa / Rogers / Toshiba |

||

|

Base Material |

AI2O3 |

||

|

Base Material Thickness (exclude conductor) |

0.15-6mm |

||

|

Thermal Conductivity |

24-170W/mk |

||

|

Soldermask Type |

Aluminum Oxide |

||

|

Tg Value |

800℃ |

||

|

Halogen Free |

No |

||

|

Breakdown Voltage |

15 KV/mm |

||

|

Dielectric Constant (MHZ) |

9.4 (1MHz); 9.1 (13GHz) |

||

|

Water Absorption |

≤0.5% |

||

|

ROHS |

Yes |

||

|

Flammability |

Grade A |

||

|

Thermal Conductivity (W/m.K, or W/m.C) |

24-170 W/mk |

||

|

Dielectric Strength |

>15 KV/mm |

||

|

Wrap & Twist |

3% |

||

| Prototype(<1m²) | Layers | Normal Service | Expedited Service |

|---|---|---|---|

|

DPC Ceramic PCB |

1 Layer |

DPC: 2 - 3 weeks |

DPC: 1.5 weeks |

|

2 Layers |

DPC: 2 - 3 weeks |

DPC: 1.5 weeks |

| Production | Layers | Normal Service | Expedited service |

|---|---|---|---|

|

DPC Ceramic PCB |

1 Layer |

DPC: 3 - 4 weeks |

DPC: 1.5 - 2 weeks |

|

2 Layers |

DPC: 3 - 4 weeks |

DPC: 1.5 - 2 weeks |

How do we control the quality of our DPC ceramic PCB?

- Select high-quality ceramic materials for optimal performance.

- Strictly controlling manufacturing processes for stability and reliability.

- Ensuring precise dimensional accuracy and component alignment.

- Conduct thorough electrical and thermal testing.

- Implementing rigorous inspection and analysis procedures.

- Subjecting PCBs to reliability and environmental tests.

- Maintaining detailed documentation for traceability.

- Continuously improving based on customer feedback and data.

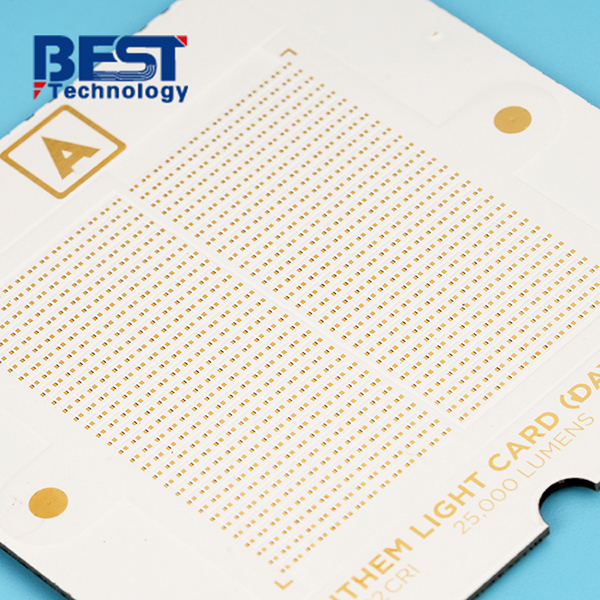

DPC ceramic PCB specification:

|

Substrate material: |

96% Al2O3 |

|

Board thickness: |

1.0mm+/-0.1mm |

|

Conductor: |

18um copper |

|

Solder mask: |

White Glass Glaze |

|

Silkscreen: |

N/A |

|

Surface finishing: |

ENEPIG 3u’’ |

|

Application: |

LED chip |

Background:

LuminaLED Technologies is mainly supplied high-performance LED for various lighting applications. They specialize in producing energy-efficient, long-lasting LED chips that deliver superior brightness and color accuracy. And be aimed to provide lighting solutions that meet the evolving needs of the market and contribute to energy conservation efforts.

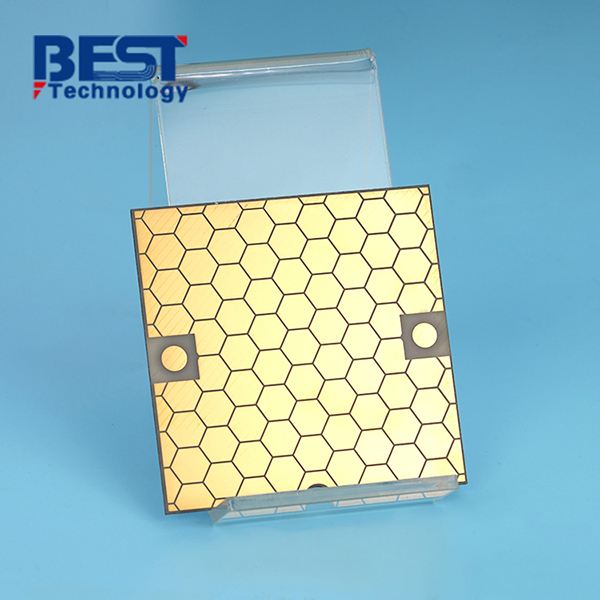

Now they faced a significant challenge in optimizing the performance and reliability of their LED chips. Conventional packaging materials used for LED chips, such as FR4, had limitations in terms of thermal management, electrical conductivity, and miniaturization. These limitations resulted in reduced brightness, increased thermal stress, and limited design flexibility for them.

Solution:

Due to the LED requiring very good heat dissipation, the size also needs to be small to match the LED, we recommended DPC ceramic PCB for them because DPC ceramic circuit boards enable precise miniaturization of LED chip packaging, allowing for compact designs and greater flexibility in product development. This feature enabled LuminaLED Technologies to create smaller, more versatile LED chip packages, expanding their range of lighting applications.

Result and Benefits:

LuminaLED Technologies expressed high satisfaction with the implementation of DPC ceramic circuit boards in their LED chip packaging and introduced two new customers for us.

HOME

HOME