DBC Ceramic PCB (Direct Bonding Copper) is a process in which ceramic powder such as alumina, aluminum nitride, or doped zirconia bonded copper foil is used on the ceramic surface, and then cast and sintered to form a ceramic substrate. Metallization is then carried out to prepare a ceramic copper clad laminate. It is a new type of process developed with the rise of chip-on-board (COB) packaging technology.

DBC substrate has the remarkable characteristics of good insulation performance, good heat dissipation performance, low thermal resistance coefficient, matching expansion coefficient, excellent mechanical performance and good welding performance. In power electronic module technology, it is mainly used as various chips (IGBT chip, Diode chip , resistors, SiC chips, etc.), the DBC substrate completes the connection of the connecting poles or connecting surfaces of the chip through the surface copper layer, and its function is similar to that of a PCB board.

-

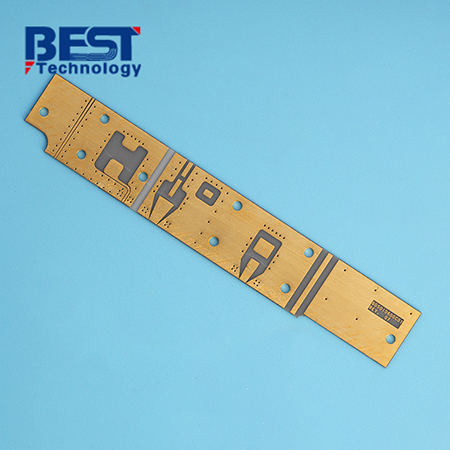

DCB Ceramic Substrate PCB For IGBT Semi-conductor

-

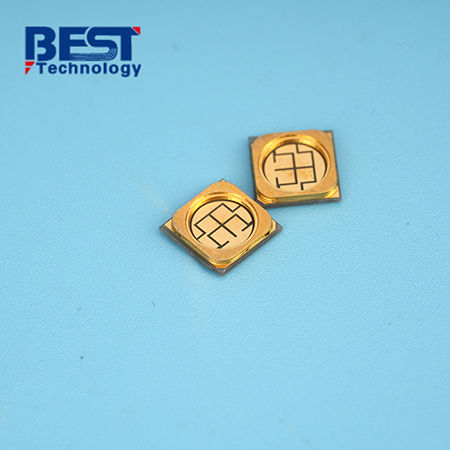

Tiny Size DBC Ceramic Substrate PCB For Scientific Education

-

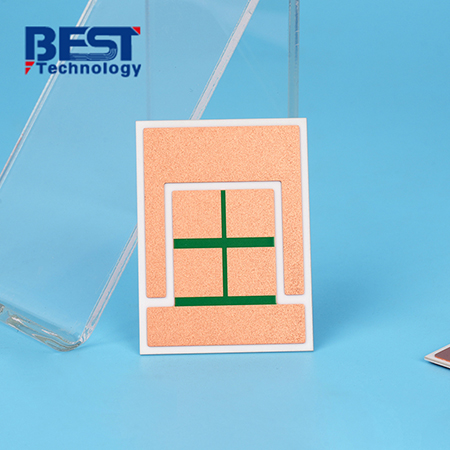

DBC/DCB Ceramic Substrate PCB For Portable Cooling Device

-

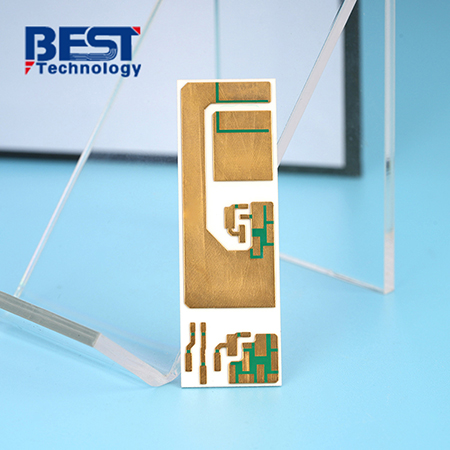

Direct Bonding Copper Ceramic Circuit Board For Automotive Components

-

Custom Wholesale Double-sided Nickel-palladium-gold DBC Ceramic PCB For Automotive Systems

HOME

HOME