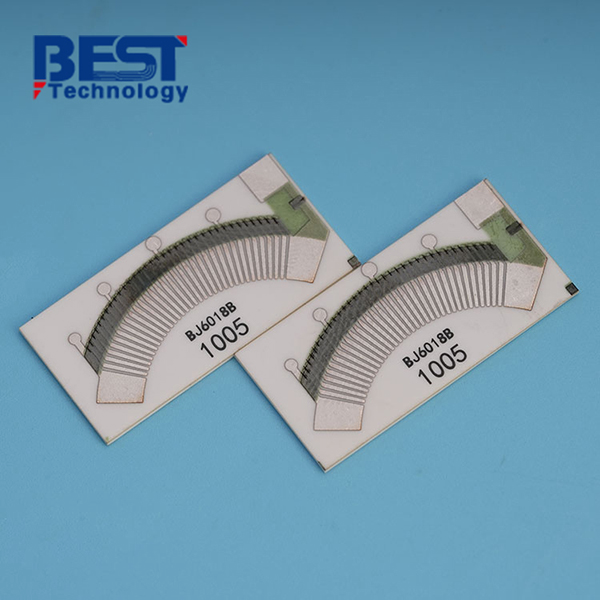

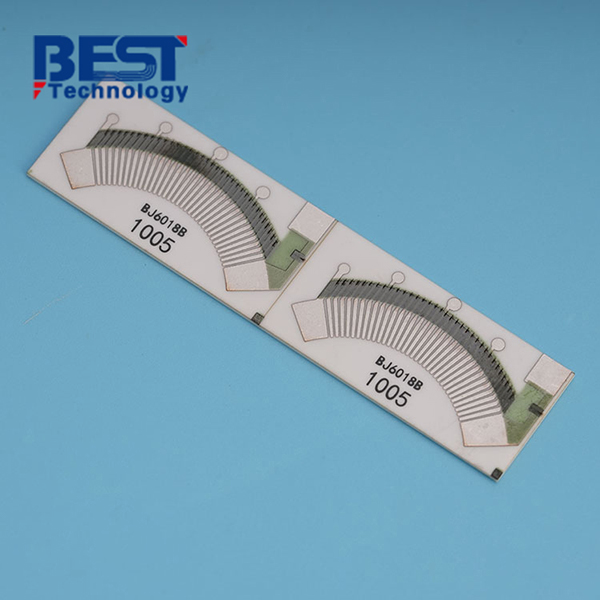

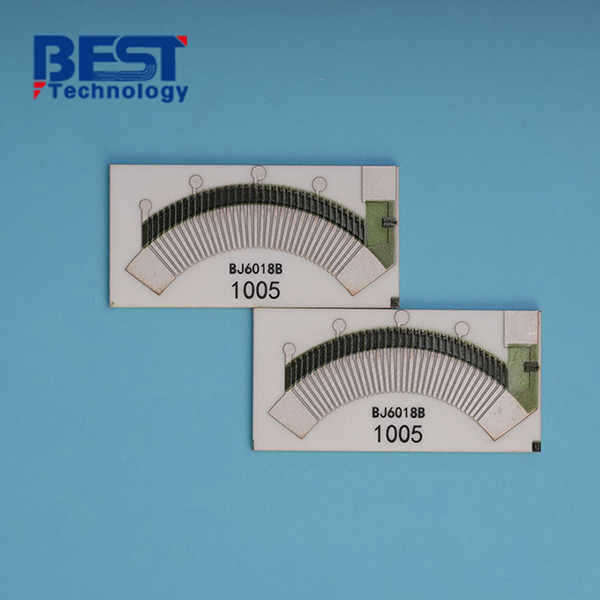

Thick Film Ceramic Substrates PCB For Auto Fuel Gauge

Substrate Material: 96% Al2O3

Board Thickness: 1.2mm+/-0.1mm

Conductor: 10um AgPd

Solder Mask: Green Glass Glaze

Silkscreen: N/A

Application: Automotive

| Item1 | Thick Film Capabilities | |||||

|---|---|---|---|---|---|---|

|

Layer Count |

1-8 Layers |

|||||

|

Max Board Dimension |

120mm×180mm |

|||||

|

Min Board Thickness |

0.254mm |

|||||

|

Max Board Thickness |

2.0mm |

|||||

|

Conductor Thickness |

7-20μm |

|||||

|

Min Line Width/Line Space |

125/150μm |

|||||

|

Substrate Type |

AIN & Si3N4 |

|||||

|

Substrate Thickness |

0.254~1.0mm |

|||||

|

Min Hole Diameter |

0.10mm |

|||||

|

Min Hole Spacing |

300μm |

|||||

|

Min PAD Ring(Single) |

0.25mm |

|||||

|

PTH Wall Thickness |

8-20um |

|||||

|

Min Solder PAD Dia |

0.25mm |

|||||

|

Min Soldermask Bridge |

150μm |

|||||

|

Min BAG PAD Margin |

0.25mm |

|||||

|

PTH/NPTH Dia Tolerance |

0.075mm |

|||||

|

Hole Position Deviation |

75μm |

|||||

|

Outline Tolerance |

Laser: +/-0.13mm |

|||||

|

Line Width/Spac Tolerance |

±20% |

|||||

|

Surface Treatment |

AgPt, AgPd, Au |

|||||

|

Thermal Stress |

7.3ppm/K |

|||||

| Item2 | Attribute | ||

|---|---|---|---|

|

Brand |

CeramTec / GTT / Huaqing / Laird / Maruwa / Rogers / Toshiba |

||

|

Base Material |

AI203 / ALN / BeO / SiO2 |

||

|

Base Material Thickness (exclude conductor) |

0.45-2.7mm |

||

|

Thermal Conductivity |

24w / 27w / 170w |

||

|

Soldermask Type |

Aluminum Nitride |

||

|

Tg Value |

800℃ |

||

|

Halogen Free |

No |

||

|

Breakdown Voltage |

>15KV/mm |

||

|

Dielectric Constant (MHZ) |

9.4 (1MHz); 9.1 (13GHz) |

||

|

Water Absorption |

≤0.5% |

||

|

ROHS |

Yes |

||

|

Flammability |

Grade A |

||

|

Thermal Conductivity (W/m.K, or W/m.C) |

24-170W/mk |

||

|

Dielectric Strength |

15KV/mm |

||

|

Wrap & Twist |

3% |

||

| Prototype(<1m²) | Layers | Normal Service | Expedited Service |

|---|---|---|---|

|

Thick Film Ceramic PCB |

1 Layer |

3 - 3.5weeks |

1-1.5 weeks |

|

2 Layers |

3 - 4 weeks |

1-1.5 weeks |

|

|

4 Layers |

3 - 4 weeks |

1-1.5 weeks |

|

| 6 Layers | 3 - 4 weeks | 1-1.5 weeks | |

| 8 Layers | 3 - 4 weeks | 1.5-2 weeks |

| Production | Layers | Normal Service | Expedited service |

|---|---|---|---|

|

Thick Film Ceramic PCB |

1 Layer |

3 - 3.5 weeks |

2 - 2.5 weeks |

|

2 Layers |

3 - 4 weeks |

2 - 2.5 weeks |

|

|

4 Layers |

3 - 4 weeks |

2 - 2.5 weeks |

|

| 6 Layers | 4 - 5 weeks | 2 - 2.5 weeks | |

| 8 Layers | 4 - 6 weeks | 2 - 2.5 weeks |

How Best Technology Serve You?

- Superior Ceramic Boards: Our expertise lies in producing ceramic boards with exceptional flatness and precise printed resistor values, ensuring high-quality performance for your applications.

- Custom Layout Services: We offer flexible custom layout services, tailoring the design of ceramic boards to perfectly match your specific requirements, guaranteeing optimal functionality and fit.

- Professional Technical Support: Our dedicated technical support team is here to assist you every step of the way, providing expert guidance and resolving any design or production issues promptly and efficiently.

- On-Time Delivery and Competitive Pricing: We prioritize on-time delivery to meet your project timelines and offer competitive pricing that aligns with your budget, providing excellent value for your investment.

- Stringent Quality Control: Our manufacturing takes place in a state-of-the-art, 2000-class dust-free workshop. Each production process undergoes rigorous quality control measures, ensuring the highest level of product quality and reliability.

- Quality Certifications and Traceability: We hold prestigious certifications, including ISO 9001, ISO 13485, and IATF 16949, showcasing our commitment to maintaining the highest quality standards. Our dedicated QC team diligently monitors all manufacturing processes, ensuring adherence to these standards. With comprehensive traceability measures in place, we can provide detailed data and documentation for complete transparency and accountability.

Background:

Sensors is a renowned automotive sensor manufacturer known for their commitment to innovation and delivering high-quality sensor solutions. They approached us with the objective of enhancing the precision, durability, and reliability of their automotive sensors to meet the evolving demands of the automotive industry.

Project challenge:

- The outline tolerance is very strict, only positive tolerance is available.

- The project requires high wear resistance, so the conductor should include high content of Palladium, but it is not easy to protect the palladium surface from oxidation.

- The quality control must be proceeded with IPC class III.

Solution:

According to the requirement, we choose thick film technology for them. Thick film ceramic circuit boards have found extensive use in automotive sensors, which play a critical role in modern vehicles. These sensors are responsible for collecting and transmitting important data related to engine performance, emissions, safety, and more. By utilizing our thick film ceramic circuit boards in sensor designs, automotive manufacturers can achieve enhanced precision and reliability.

In this case, our ceramic circuit boards facilitate precise signal transmission, minimizing signal loss and interference. The excellent thermal management properties of the boards ensure consistent performance across a wide range of operating temperatures. Additionally, their robustness and resistance to harsh automotive conditions, such as vibration and moisture, ensure the longevity and durability of the sensors.

Result and Benefits:

We got consistent orders from Sensors, and they provide forecast to us every year, that we can prepare the raw material in advance, and produce the ceramic PCBs within 1.5weeks after receiving the purchase order.

HOME

HOME