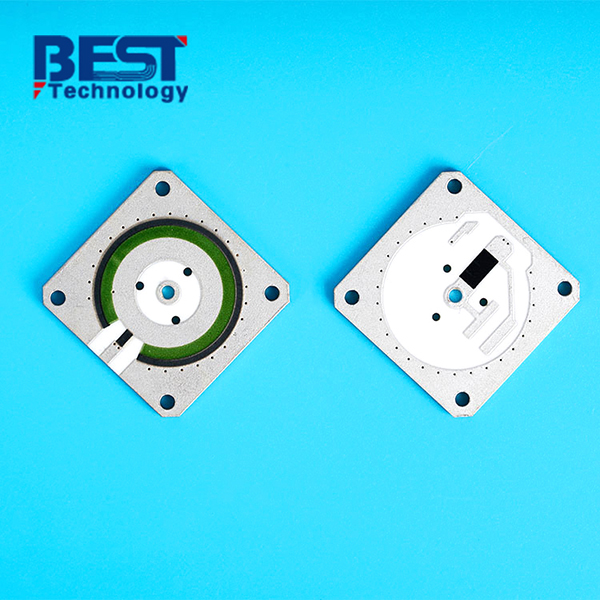

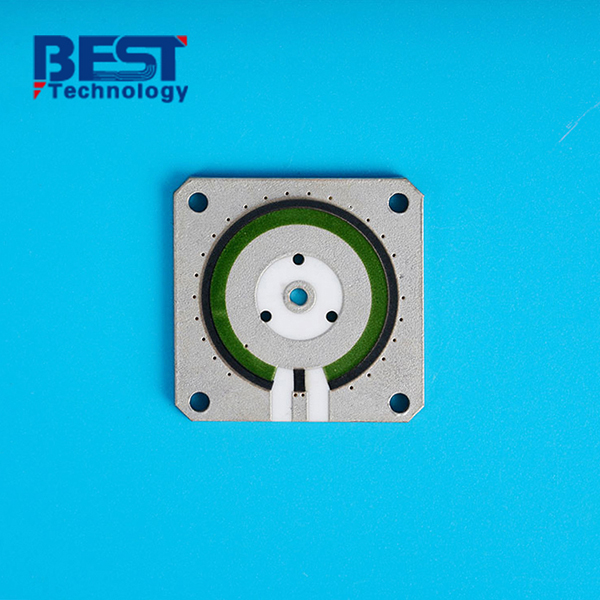

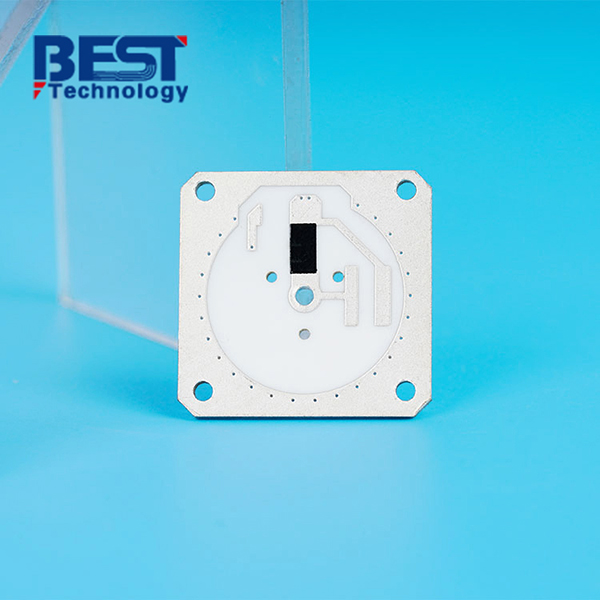

96% Al2O3 Thick Film Ceramic Substrate PCB For Defense

Substrate Material: 96% Al2O3

Board Thickness: 1.0mm+/-10%

Conductor: 10-15um AgPd

Solder Mask: Green Glass Glaze

With Printed Resistor: N/A

Application: Defense

| Item1 | Thick Film Capabilities | |||||

|---|---|---|---|---|---|---|

|

Layer Count |

1-8 Layers |

|||||

|

Max Board Dimension |

120mm×180mm |

|||||

|

Min Board Thickness |

0.254mm |

|||||

|

Max Board Thickness |

2.0mm |

|||||

|

Conductor Thickness |

7-20μm |

|||||

|

Min Line Width/Line Space |

125/150μm |

|||||

|

Substrate Type |

AIN & Si3N4 |

|||||

|

Substrate Thickness |

0.254~1.0mm |

|||||

|

Min Hole Diameter |

0.10mm |

|||||

|

Min Hole Spacing |

300μm |

|||||

|

Min PAD Ring(Single) |

0.25mm |

|||||

|

PTH Wall Thickness |

8-20um |

|||||

|

Min Solder PAD Dia |

0.25mm |

|||||

|

Min Soldermask Bridge |

150μm |

|||||

|

Min BAG PAD Margin |

0.25mm |

|||||

|

PTH/NPTH Dia Tolerance |

0.075mm |

|||||

|

Hole Position Deviation |

75μm |

|||||

|

Outline Tolerance |

Laser: +/-0.13mm |

|||||

|

Line Width/Spac Tolerance |

±20% |

|||||

|

Surface Treatment |

AgPt, AgPd, Au |

|||||

|

Thermal Stress |

7.3ppm/K |

|||||

| Item2 | Attribute | ||

|---|---|---|---|

|

Brand |

CeramTec / GTT / Huaqing / Laird / Maruwa / Rogers / Toshiba |

||

|

Base Material |

AI203 / ALN / BeO / SiO2 |

||

|

Base Material Thickness (exclude conductor) |

0.45-2.7mm |

||

|

Thermal Conductivity |

24w / 27w / 170w |

||

|

Soldermask Type |

Aluminum Nitride |

||

|

Tg Value |

800℃ |

||

|

Halogen Free |

No |

||

|

Breakdown Voltage |

>15KV/mm |

||

|

Dielectric Constant (MHZ) |

9.4 (1MHz); 9.1 (13GHz) |

||

|

Water Absorption |

≤0.5% |

||

|

ROHS |

Yes |

||

|

Flammability |

Grade A |

||

|

Thermal Conductivity (W/m.K, or W/m.C) |

24-170W/mk |

||

|

Dielectric Strength |

15KV/mm |

||

|

Wrap & Twist |

3% |

||

| Prototype(<1m²) | Layers | Normal Service | Expedited Service |

|---|---|---|---|

|

Thick Film Ceramic PCB |

1 Layer |

3 - 3.5weeks |

1-1.5 weeks |

|

2 Layers |

3 - 4 weeks |

1-1.5 weeks |

|

|

4 Layers |

3 - 4 weeks |

1-1.5 weeks |

|

| 6 Layers | 3 - 4 weeks | 1-1.5 weeks | |

| 8 Layers | 3 - 4 weeks | 1.5-2 weeks |

| Production | Layers | Normal Service | Expedited service |

|---|---|---|---|

|

Thick Film Ceramic PCB |

1 Layer |

3 - 3.5 weeks |

2 - 2.5 weeks |

|

2 Layers |

3 - 4 weeks |

2 - 2.5 weeks |

|

|

4 Layers |

3 - 4 weeks |

2 - 2.5 weeks |

|

| 6 Layers | 4 - 5 weeks | 2 - 2.5 weeks | |

| 8 Layers | 4 - 6 weeks | 2 - 2.5 weeks |

With thick film technology, we have the capability to incorporate resistors, electric capacitors, conductors, semiconductors, and interchangeable conductors onto ceramic boards. This is achieved through printing and high-temperature sintering during the manufacturing process. We can create uniform resistors with the same value or customize them to have different values for various resistors on the same board.

Why Choose Us?

- Experience and Reputation: With years of industry experience, Best Technology has earned a strong reputation for reliability and excellence.

- Superior Quality: Our advanced manufacturing processes and strict quality control measures ensure that our thick film ceramic boards meet the highest thermal stability, chemical resistance, and electrical performance standards.

- Customized Solutions: We offer tailored solutions to meet your specific requirements, collaborating closely with you to create custom thick film ceramic boards in terms of dimensions, shapes, and technical specifications.

- Diverse Applications: Our thick film ceramic boards find applications in various industries, delivering exceptional performance and reliability across sectors such as chemicals, electronics, medical, and aerospace.

- Quality Assurance and Support: We prioritize quality and provide prompt technical assistance and solutions to ensure your satisfaction throughout the project.

Background:

The customer is a renowned defense contractor specializing in the development of advanced military radar systems. With a longstanding track record of delivering state-of-the-art technology to defense organizations, they have firmly established themselves as a dependable and innovative supplier within the defense industry. Their area of expertise lies in the creation of radar systems for diverse applications, including surveillance, air defense, and reconnaissance.

Seeking collaboration with a trusted electronics manufacturer, the customer aimed to obtain a vital component for their latest military radar system. They required a circuit board solution capable of enduring severe environmental conditions, ensuring high signal integrity, and enabling swift data processing for real-time target tracking.

Thick film ceramic circuit boards were selected due to their exceptional ruggedness, thermal management properties, and reliability. These circuit boards are produced by depositing multiple layers of conductive and dielectric materials onto a ceramic substrate, resulting in a dense and robust interconnect system capable of withstanding extreme temperatures, vibrations, and humidity.

Solution:

The thick film ceramic circuit boards were integrated into the signal processing and control unit of the military radar system. These boards facilitated the efficient transmission of radar signals, precise data acquisition, and complex digital signal processing. The high thermal conductivity of the ceramic material helped dissipate heat generated during operation, ensuring optimal performance even in demanding environments.

Result and Benefits:

This successful implementation of thick film ceramic circuit boards in a military radar system demonstrates the customer's commitment to leveraging advanced electronic technologies to meet the demanding requirements of defense applications. Their collaboration with us showcases their focus on delivering high-performance radar systems that support military operations and provide crucial situational awareness to defense organizations. In another way, it also means Best Technology has entered the defense fields successfully.

HOME

HOME