Systematic Management

Good quality comes from strict production management and rich industry experience. Factory manufacturing management is divided into: incoming material inspection, mechanical update, staff training and formulation of relevant standards. In 17 years, we have continuously optimized management, improved the quality control system, and challenged and served more projects.Quality Control

Quality Control is the monitoring cor of a top Ceramic PCB Company, also the only way for sustainable development!

Best Technology has obtained ISO 9001, IATF 16949, UL, RoHS, SGS certification, with four cores "Raw Material Guarantee, Pre-production Inspection, In Process Quality Control, Rigorous Testing And Inspection". In the past, what we did not do well is where we will improve in the future.

How Do We Ensure the Quality and Reliability?

01

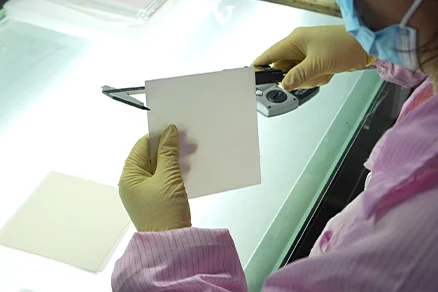

Substrate Thickness Check

Manual DetectionManually testing the thickness of the substrate is suitable for rapid proofing of ceramic plate samples, which can reduce the time of the process.

02

Substrate Width Measurement

Manual DetectionThe substrate width is measured in order to meet the design dimensions required by customers before mass production.

03

X-Y Size Measurement

Mechanical Precision MeasurementThe X-Y axis mechanically measures the size of the ceramic PCB, which can be more accurate than manual inspection.

04

X-ray Inspection Machine

The naked eye is not an error of recognition!Under the premise of not damaging the circuit board, AOI can detect defects hidden on the surface, greatly reducing the delivery of inferior finished products. At present, it is widely used in PCB production industry.

05

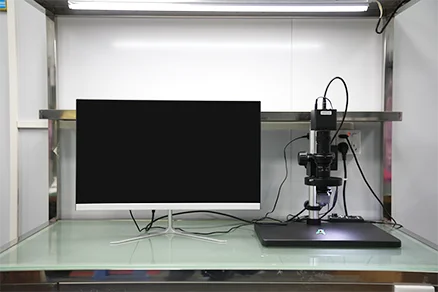

Magnifying Glass Test Substrate

Super careful visual inspection and identificationCompared with the old-fashioned magnifying glass, the vision connected to the computer is more intuitive, and it is convenient to identify the defects of the ceramic PCB.

06

Flying Probe Detection

Mass production, fast inspection way.Flying probe test is usually used in mass production, which can greatly reduce the detection time of aperture, conductivity, short circuit, resistance and other performance.

07

First Finished Product Inspection

Resistance, voltage, conductivity, temperature resistance, etc.Ceramic PCB samples that provide rapid proofing services need to pass the first article test before they can be produced in small batches to mass production. Only in line with the customer's performance parameter values can it be put into production.

08

Two-way Track AOI

Automated Optical InspectionCompared with SPI, AOI can detect more subtle open circuit problems. Dual-track AOI doubles the efficiency and can complete the delivery on time.

09

Appearance Test Magnifying Glass

Shape qualified inspectionThe shape inspection magnifying glass can check the shape edge, overall shape, circuit layout and other qualified conditions of the ceramic substrate.

Product Specification

-

DPC (Direct Plating Copper) PCB

DPC (Direct Plating Copper) PCB -

DBC (Direct Bonding Copper) PCB

DBC (Direct Bonding Copper) PCB -

AMB (Active Metal Brazing) PCB

AMB (Active Metal Brazing) PCB

HOME

HOME