What is thick film ceramic PCB?

The world of electronics is rapidly evolving, and with it, the demand for smaller, more efficient, and more reliable electronic devices is increasing. Printed Circuit Boards (PCBs) are critical components of almost all electronic devices, providing the means to connect and control electrical components. However, traditional PCBs made of fiberglass and copper are facing limitations in terms of performance and durability as electronic devices become more complex and miniaturized. This has led to the development of new materials and technologies, such as Thick Film Ceramic PCBs.

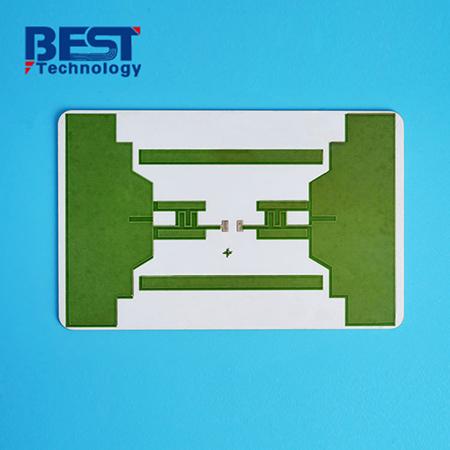

What is Thick Film Ceramic PCB?

Thick Film Ceramic PCB, also known as Thick Film Resistor Ceramic PCB, is a versatile technology that allows for the integration of reliable carbon resistors, conductors, semi-conductors, and interchangeable conductors onto a ceramic substrate using standard PCB processing techniques. After the printing and high-temperature sintering process, the resistors can be laser trimmed to achieve high tolerance conditions, allowing for the creation of resistors with the same or different values on a single board. What’s more, the finished ceramic board with high tolerance conditions can adjust the resistance value by trimming printing resistors, so we can make all the resistors with the same value, or each resistor with a different value on a board.

Thick Film Ceramic PCB solution makes resistors embedded into printed circuit boards more complex, but more versatile than the selection of surface-mounted passive components. This frees up the surface space for the placement of more active components that increase functionality.

The Future of Thick Film Ceramic PCB

Thick Film Ceramic PCB technology is a new material that will improve the process of embedded resistors by eliminating the need for special termination treatment, such as immersion silver, silver palladium or gold palladium, and increase the reliability performance with a stable binder system. Thus far, the environmental and mechanical testing of Thick Film Ceramic PCB processing has also been successful. Continuing to test and formulate higher resistivity values will prove that the thick film resistor technology has a future in the embedded passives market.

The same as FR4 printed circuit board, thick film Ceramic can be composed of active and passive components (Resistors, IC, Diode, Capacitors, Inductors, Connectors) by using various types of technical like SMT, Wire Bonds, COB, TAB. Mounted with pin connection and package also named as Thick Film Hybrid Circuit.

In a word, Thick Film Ceramic PCB Technology can be used to deposit any combination of fixed resistors, switches, sensors, potentiometer tracks and conductors onto virtually any size, shape or PCB form.

Characteristics of Thick Film Ceramic PCB

1. Ceramic Substrate can be 96% or 98% Alumina (Al2O3) or Beryllium Oxide (BeO), thickness range: 0.25, 0.38, 0.50mm, 0.635mm (default thickness), 0.76mm, 1.0mm. Thicker thicknesses such as 1.6mm or 2.0mm can be customized too.

2. Conductor layer material is silver palladium (AgPd), gold-palladium (AuPd), or Mo/Mn+Ni(ONLY for Ozone).

3. Thickness of conductor >= 10 microns (um), and Max can be 20 microns (0.02mm).

4. Min trace width and space for volume production:0.30mm & 0.30mm, 0.20mm/0.20mm are also okay but the cost will be higher, and 0.15mm/0.20mm is only available for prototype.

5. Tolerance for final trace layout will be +/-10%.

6. Both gold and silver palladium is workable for gold-wire bonding, but customer needs to mention that so that we can use special silver palladium which is suitable for that artwork.

7. Gold palladium is much more expensive than silver, about 10~20 times higher.

8. The more different resistor values on the same board, the more expensive the board will be.

9. Normally layers are 1L and 2L (with plated through hole (PTH), and plated material is the same as the one used for conductor).

10. Solder mask is also available upon request, working temperature >500 C, and the color is semi-transparent.

Engineering Specifications

For Typical applications:

1. Printing Accuracy: ±2 mil

2. Printing Size: 210mm*297mm (Max)

3. Line width, Line gape:6/ 6mil (Min)

4. Resistor value: 40mΩ~1000MΩ

5. Precision resistor: ±1%,±2%,±5%,±0.5%

6. Resistor Accuracy: Absolute ±2%, Ratio ±0.1%

7. Laser trim: Functional trim

8. Print not only on Ceramic but also on Stainless, FR4, Flexible PCB

9. Die assembly and AI wedge bonding

10. Lead out: SIP and DIP, Pitch2.54mm and1.78mm

11. Conformal coating and molding

12. Having the ability to work in gasoline (lead-free gasoline, ethanol gasoline, methanol gasoline, or low-grade gasoline) & diesel oil.

Here is BSTCeramicPCB's Capability for Thick Film Ceramic PCB

| Item | Thick Film Ceramic PCB |

| Layer | 10 Layers |

| Max Board Dimension | 200*200mm |

| Min Board Thickness | 0.25mm |

| Max Board Thickness | 2.0mm |

| Conductor Thickness | 5-13um |

| Min Line Width/Space | 6/8mil (0.15/0.20mm) |

| Substrate Material | Al2O3, AlN, BeO, ZrO2 |

| Substrate Thickness | 0.25, 0.38, 0.50, 0.635, 0.80, 1.0, 1.25, 2.0mm |

| Min Hole Diameter | 10mil (0.25mm) |

| Min Soldermask Bridge | 12mil (0.30mm) |

| Min BAG PAD Margin | 12mil (0.30mm) |

| PTH/NPTH Tolerance | PTH: ±4mil (0.1mm); NPTH: ±2mil (0.05mm) |

| Hole Position Deviation | ±4mil (0.1mm) |

| Outline Tolerance |

+0.2/-0.05mm (laser) +0.25/0.20mm (Die Punch) |

| Line Width/Space Tolerance | ±5mil (0.125mm) |

| Surface Finishing/Treatment | AgPd, AuPd, Mn/Ni |

Application in Automotive

1. Ignition module

2. Voltage regulator module

3. Slow motor control module

4. Thick film resistor for fuel level (Be used in both cars and motorcycles)

5. Blower resistor for fan motor

6. Mass airflow sensor

7. Throttle position sensor (TPS)

8. Rotary position sensor

9. Wiper speed

10. Automatic leveling system (ALS)

11. Accelerator Pedal Position Sensor

12. Fuel level sensor

Other Application

Home Appliances

Satellite Signal transmission equipment

Light dimmers

High-frequency wireless communication

Heavy duty equipment

Speed control for hand power tools

Commercial Phased Array Network

Power conversion devices

Electric regulator

HOME

HOME