Ceramic PCB Assembly

The PCB assembly is mounting bare PCB boards with electronic components to make them into semi-finished devices. This process includes PCBA manufacturing and PCBA tests. In Bstceramic, PCBA tests go through the whole process to ensure 100% product quality and customer satisfaction.Ceramic PCB Assembly

Ceramic PCB Assembly is the process of assembling Ceramic Substrates And IC Components in Original Factory

- • One-stop EMS solution without minimum order requirements

- • Own PCBA factory, in-house R&D team, 10+ engineers, 200+ technicians

- • Our PCB assembly includes BOM check, first article inspection, and functional testing

- • ISO, IATF, REACH, RoHS, and UL certified standard compliances

- • Free DFT/DFM/DFA/DFX services

- • Fast delivery, instant online quotation, reasonable price

- • Our online AOI is 3D-scanning, which is better than other PCB assemblers

How Do We Ensure the Quality and Reliability?

01

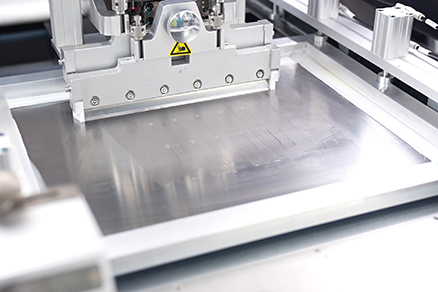

Soldering Paste Printing

Greatly reduces the size of the circuit boardBest Technology uses a fully automatic stencil printer and a squeegee to apply the solder paste to the board. By dragging the scraper on the stencil, adjust the appropriate pressure value, and evenly cover the circuit board with solder paste. Blades are usually made of metal.

Since the solder paste acts as an adhesive, it connects the surface components to the pads on the board. And it also provides electrical and thermal connections. At the same time, the use of solder paste does not require solder wire, which is very suitable for printed circuit boards.

02

Solder paste 3D SPI detector

3D SPI Solder Paste InspectionIn the production of ceramic PCBs, 3D SPI (Solder Paste Inspection) detectors ensure the quality of solder paste application on printed circuit boards (PCBs). The primary function of a 3D SPI detector is to check and verify the accuracy of solder paste deposition on the PCB before placing components. Helps ensure that the right amount of solder paste is applied to the correct location on the board, preventing issues such as insufficient or excessive solder.

03

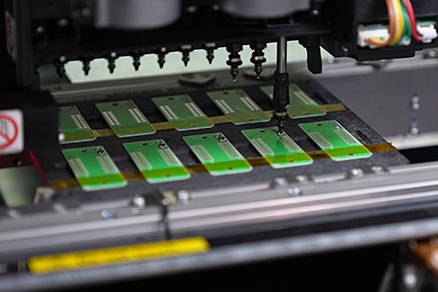

Surface Mounted Technolog (SMT)

SMT is not SMDSMT is to assemble the electronic components to the corresponding positions of the PCB through the automatic equipment setting according to the design drawings. PCBA service can help customers save a lot of time when it comes to PCB needs from batch to mass production, and it is also a troublesome thing to purchase different electronic components at the same time. SMD simply refers to electronic components, not production processes.

04

First Piece Testing

Ceramic PCB First Article InspectionFirst-piece testing, also known as first-article inspection or first-article testing, is a quality control practice in the production of ceramic plates (or any other manufactured product). The primary purpose of first-piece testing is to ensure that the initial product produced in a production run meets the specified design and quality standards. The first piece produced is subjected to a thorough examination to verify that it conforms to the design specifications and engineering drawings.

05

Reflow Soldering

Manual inspection is the last guarantee:Under the premise that the reflow temperature is 13°C lower than the melting temperature, reflow soldering fixes the surface mount components on the PCB substrate. Solder particles in solder paste are susceptible to oxidation during air reflow, especially if the flux is lost and exposes the solder particles and/or the oxidation resistance of the flux is insufficient to protect the solder particles. This can lead to a cosmetic defect commonly known as "graping".

06

AOI (automated optical inspection)

Check for problems invisible to the naked eyeBest Technology employs Automated Optical Inspection (AOI) which is an automated visual inspection of PCB manufacturing where cameras automatically scan the device under test for missing electronic components and quality defects.

07

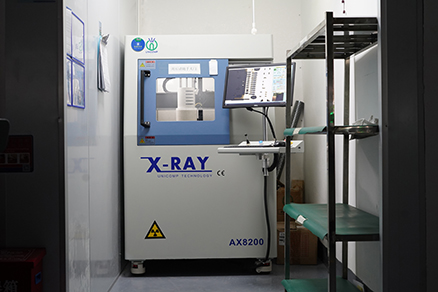

X-Ray Inspection

When Mass ProductionAn X-ray inspection is a non-destructive inspection method that uses radiography and is mainly used to identify CUI (corrosion under insulation).

08

Manual Soldering

Artificial connectionManual soldering is a traditional method of soldering leaded components to a PCB. It is generally used for small production runs, laboratory assembly work, rework/repair, and addition of extra components on a machine soldered assembly.

09

Touch-up And Cleaning

Manual quality inspectionThe repair and cleaning of the substrate includes automatic cleaning of mechanical equipment and artificial defect repair. Defective substrates after passing the AOI inspection need to be manually repaired, for example: tight wiring and vias, poor connection, insufficient board thickness, insufficient resistance, etc.

10

IC-programming

Infuse Soul into the SubstrateThe process of loading a computer program into an IC circuit so that it can operate normally is defined as IC Programming.

11

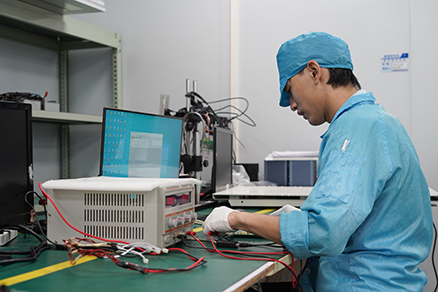

FCT (functional tests)

Avoid CostFunctional testing is to ensure that each component can meet the standard and operate normally. Avoid too many inferior PCBs after being put into mass production. We usually check how the performance values of resistors, sensors, and capacitors meet the standards, and use corresponding testing equipment.

12

Thermal Aging Testing

Thermal aging tests are performed to determine the lifespan of PCB boards. It tests the ability of PCB components to withstand extreme temperatures for extended periods of time. The reliability of components on a printed circuit board degrades exponentially over time. This will eventually cause the PCB to fail due to differences in the coefficient of thermal expansion (CTE) of the PCB materials.

Inspection Data Report

-

Soldering Paste Printing

Soldering Paste Printing -

SMT

SMT -

Nitrogen Reflow Soldering

Nitrogen Reflow Soldering -

AOI Inspection

AOI Inspection -

Manual Soldering

Manual Soldering -

X-Ray Inspection

X-Ray Inspection -

Touch-up And Cleaning

Touch-up And Cleaning -

IC-programming

IC-programming

HOME

HOME