Ceramic PCB: An Overview Application in Computer System

In the electronics world of technology, printed circuit boards (PCBs) play a vital role in the functioning of various electronic devices, including computers. Traditionally, PCBs have been predominantly made using fiberglass or other similar materials. However, advancements in technology have led to the emergence of Ceramic PCB as a potential alternative. In this article, we will explore the concept of ceramic PCBs and evaluate their viability in computer applications.

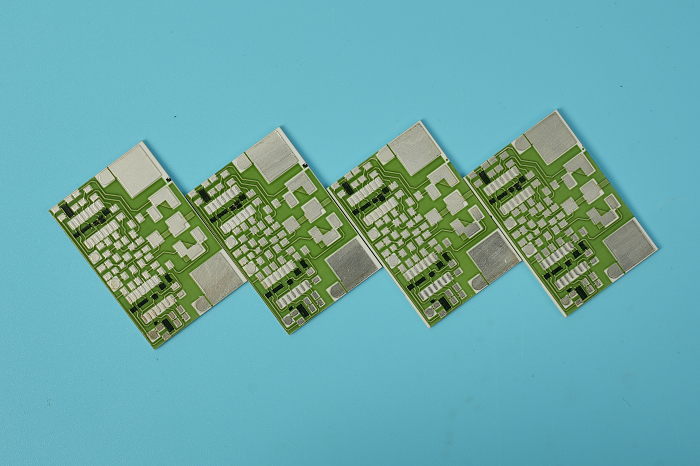

Ceramic PCBs, also known as ceramic printed circuit boards, are a type of PCB that utilizes ceramic as the base material instead of traditional substrates like fiberglass or epoxy. Ceramic materials such as aluminum oxide (Al2O3) and aluminum nitride (AlN) offer unique properties that make them suitable for specific applications, including high-power electronic devices. In the current industry, there are several technologies can make ceramic circuit board, such as DPC, DBC, Thick film, AMB, LTCC and HTCC technology. Each technical has its own properties.

Benefits of ceramic PCB be used in computer

There are numerous benefits we can get if apply ceramic PCB in computer, for example:

- High temperature resistance: Advanced ceramics have good high temperature resistance and can work for a long time in a high temperature environment - such as CPU heat sinks and other components in computers.

- Corrosion resistance: Ceramic PCBs can work in harsh environments for a long time - such as the storage device protection layer in the computer and other components.

- Wear resistance: It can work for a long time in a high frequency and high-speed working environment - such as capacitors, resistors, electronic ceramics and other components in computers.

- High precision performance: Good dimensional stability and accuracy, which can achieve high precision manufacturing and assembly in small size components - such as miniature electronic components in computers.

- Electrical performance stability: Good electrical performance stability, can work stably for a long time in complex circuit environments such as high frequency, high voltage, high temperature - such as microwave ceramics, filters, oscillators and other components in computers.

- Ecological and environmental protection: Compared with traditional materials, advanced ceramic materials have lower energy consumption and less environmental pollution, which meets the requirements of modern industrial ecological and environmental protection.

Challenges in Using Ceramic PCBs

While ceramic PCBs offer several advantages, they also come with certain challenges that need to be addressed:

Higher Cost: Ceramic PCBs tend to be more expensive compared to traditional PCBs due to the specialized manufacturing processes and the cost of ceramic materials.

Brittleness: Ceramic materials can be brittle, which makes them more susceptible to cracking or breaking if subjected to mechanical stress or mishandling.

Complex Manufacturing: The manufacturing process for ceramic PCBs is more complex and requires specialized expertise, which may lead to higher production costs.

Where can Ceramic PCB Use in Computer?

When it comes to computers, ceramic PCBs can be used in various components and modules, including:

1. Central Processing Units (CPUs)

CPU is the key part in computer, it can be employed in its packaging, helping to manage the thermal dissipation and ensuring efficient heat transfer away from the processor.

2. Graphics Processing Units (GPUs)

Ceramic PCBs are also suitable for GPUs, especially in high-performance gaming or professional graphics cards. The excellent thermal conductivity helps in dissipating the heat generated by the GPU and preventing overheating and maintaining the optimal performance.

3. Memory Modules

Ceramic PCBs have very good high-frequency performance and signal integrity, these properties enable to faster data transfer rates and improved memory performance. So, it is a good choice for computer memory modules such as random-access memory.

4. Motherboards

Motherboards are extreme important in communication devices such as mobile phone, computers. Certain sections of computer motherboards can benefit from the use of ceramic PCBs. These include power delivery circuits, where the high thermal conductivity and temperature resistance of ceramics aid in efficient power distribution and heat dissipation.

Except above all, ceramic substrate also can be used in the manufacturing of SSDs, particularly in the control and interface circuitry.

Future Prospects of Ceramic PCBs

The utilization of ceramic PCBs in computer systems and other electronic devices is expected to grow in the coming years. As technology advances and electronic components become more powerful and compact, the need for effective thermal management becomes crucial. Ceramic PCBs offer a viable solution to address this requirement.

Further research and development in ceramic materials and manufacturing techniques are likely to result in improved performance, reduced costs, and wider adoption of ceramic PCBs in different industries. As the demand for high-performance computing and advanced electronic systems continues to rise, the unique properties of ceramic PCBs position them as a promising technology for the future.

HOME

HOME