Silver Paste: The Best Conductor Material for Via Holes in Thick Film Ceramic Boards

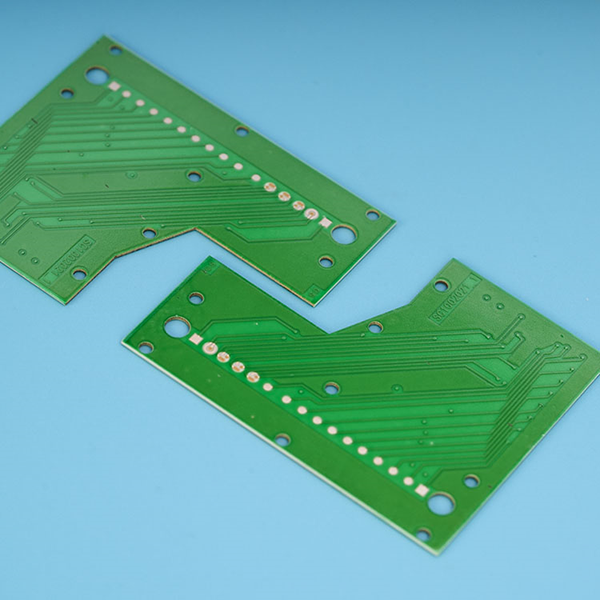

In our last article, we know that it is feasible to design via holes in thick film ceramic circuits, so today we will delve into why silver paste is chosen as the conductor material for via holes in thick film ceramic boards, and the importance of a special material in achieving a reliable and efficient electrical connection.

Silver paste is a conductive material that is usually used to make via holes in thick film ceramic boards. Generally, when manufacturing via holes, manufacturers will use special silver paste to fill them, because compared with several other conductor materials, silver paste has the following excellent characteristics:

1. High conductivity

Silver has excellent conductivity, allowing efficient and reliable electrical connections in via holes. When silver paste is used in vias, it creates a continuous conductive path that enables seamless electrical connections between different layers of a circuit. Below is a chart comparing the electrical conductivity of silver with other metals:

| Comparison Of Physical Properties | ||||||

| Metal Material | Ag | Cu | Au | Al | Zn | Pb |

|

Conductivity (Based on Ag's conductivity of 100) |

100 | 99 | 74 | 61 | 27 | 7.9 |

2. Compatibility with ceramic substrates

In order to adapt to the ceramic substrates used in thick film ceramic boards, a special silver paste has been prepared. It has a similar coefficient of thermal expansion (CTE) to ceramic materials, which minimizes the risk of stress or damage to the board during the manufacturing process and thermal cycling.

3. Chemical stability and reliability

Silver has good chemical stability in the general environment, and it is not easy to oxidize, corrode or chemically react with other materials, which can ensure the long-term reliability of vias. This enables the silver paste to maintain relatively stable electrical conductivity when made via holes and is not easily affected by the external environment.

4. Sintering performance

Silver paste usually needs to be sintered when making via holes in ceramic boards, that is, to sinter silver particles at high temperatures and form a dense conductive layer, which can ensure good adhesion and electrical performance in through holes even at high temperatures. Silver has a lower sintering temperature and sintering performance, which helps to form a dense, smooth and conductive layer on the ceramic plate.

5. Adhesion and rheology

Silver paste can usually form good adhesion on the ceramic plate, can form a firm bond with the ceramic substrate, and is not easy to fall off or peel off. This ensures accurate and reliable deposition of silver paste on the ceramic board, which is critical to via-hole quality and performance.

In summary, the use of special silver pastes ensures reliable and efficient electrical connections between different layers of circuits, thereby providing high-performance thick-film ceramic boards for various electronic applications. Careful selection and use of suitable conductor materials is the key to achieving reliable and high-quality thick film ceramic boards.

It should be noted that with the development of technology, there are also some other conductive materials, such as copper, aluminum, gold, etc., which can also be used to make via holes in ceramic boards, but silver paste has excellent electrical conductivity and chemical stability. It has traditionally been widely used due to its properties, sinterability and adhesion. The specific choice of conductive material needs to be comprehensively evaluated and selected according to factors such as actual application requirements, manufacturing process, and cost.

HOME

HOME