Silicon Printing Circuit Boards For Advancing Electronics

In the ever-evolving world of electronics, innovation is a constant force. As our demands for smaller, faster, and more powerful devices grow, so does the need for advanced technologies to support these demands. One such technology making a significant impact in the semiconductor and microelectronics industry is Silicon PCBs (Printed Circuit Boards). These sophisticated substrates, often referred to as silicon interposers, are revolutionizing the way we design and manufacture electronic systems.

1. Understanding Silicon Circuit Boards

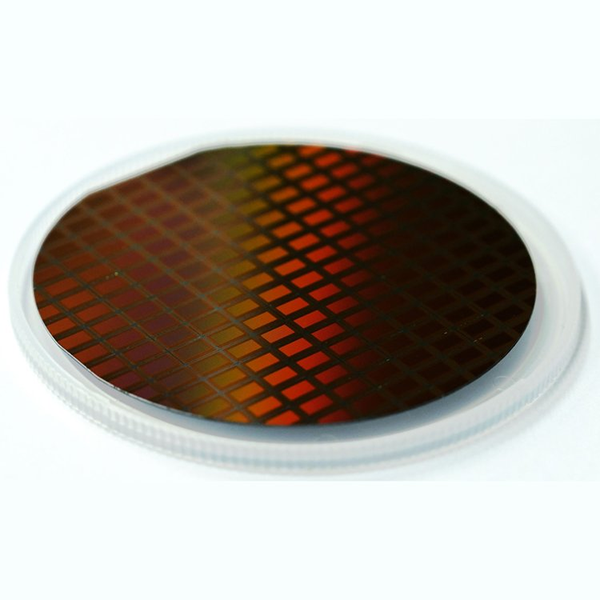

Silicon PCBs represent a departure from traditional PCBs, introducing a whole new level of complexity and performance. Instead of using conventional materials like FR-4 or metal-core substrates, Silicon PCBs are constructed using silicon wafers as the base material. Silicon, with its remarkable properties, is an ideal candidate for use in advanced electronic systems. It's an excellent conductor of heat, offers high electrical efficiency, and is capable of carrying out complex functions.

The term "silicon interposer" refers to a silicon-based substrate that is used to mount and interconnect various electronic components. The key distinction is the use of silicon as the primary substrate, which brings several advantages over traditional PCBs.

2. Manufacturing Process

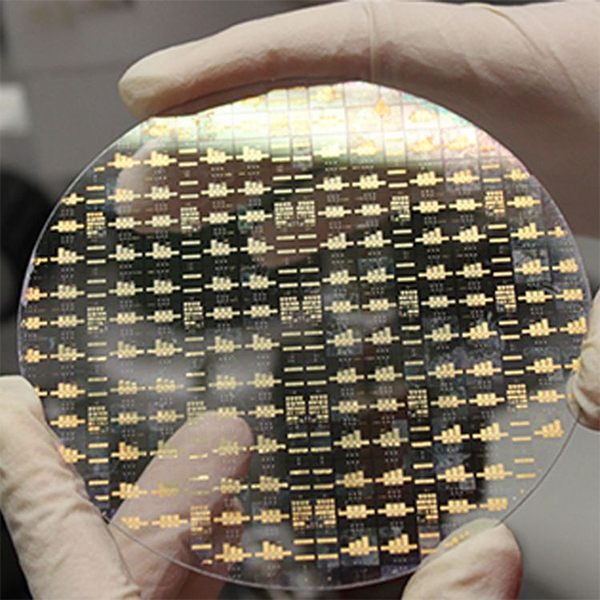

The manufacturing process of Silicon Printing Circuit Boards is a complex and precise undertaking. It involves the fabrication of silicon interposers, through-silicon vias (TSVs), and intricate interconnects.

Silicon wafers, typically used in semiconductor manufacturing, serve as the foundation for Silicon PCB Boards. These wafers are often thin and precisely processed to provide a smooth and consistent surface. The fabrication of TSVs, which are vertical electrical connections passing through the silicon interposer, is a critical step. TSVs enable efficient signal routing between different layers of the semiconductor stack, reducing signal transmission delays and improving overall system performance.

The manufacturing process requires specialized equipment and expertise, making it more intricate and costly than traditional PCB manufacturing. However, the benefits it offers in terms of performance, thermal management, and miniaturization justify the investment.

3. Applications of Silicon Ceramic PCBs

Silicon PCBs find application across a diverse range of industries, playing a pivotal role in various high-performance electronic systems. These include:

Microelectronics: Silicon Substrate PCBs are indispensable in microelectronics, enabling the integration of multiple semiconductor components with minimal footprint. This is particularly valuable in applications like mobile devices, where space is at a premium.

High-Performance Computing: Silicon Based PCBs contribute to the high-speed, high-density interconnects required in data centers and supercomputers. Their ability to manage heat efficiently is crucial in these demanding environments.

Telecommunications: In the telecommunications industry, Silicon PCBs support the development of advanced communication infrastructure, such as 5G and optical networking equipment.

Advanced Packaging Technologies: Silicon Printed Circuit Boards are a cornerstone of advanced packaging technologies, including system-in-package (SiP) and system-on-chip (SoC) solutions. These technologies are essential in modern electronics.

To illustrate their real-world impact, consider the case of a high-performance graphics card. Silicon Substrate PCBs enable the integration of multiple memory chips, processors, and connectors in a compact form factor, leading to the exceptional performance we see in gaming and professional graphics cards.

4. Advantages and Benefits

The adoption of Silicon Ceramic PCBs is driven by the numerous advantages they offer:

Enhanced Performance: Silicon PCB Boards enable faster signal transmission and data processing due to their low resistance and capacitance. This leads to improved overall system performance.

Thermal Management: The exceptional thermal conductivity of silicon helps dissipate heat effectively. This is crucial for high-power applications, preventing overheating and ensuring reliability.

Miniaturization: Silicon PCBs support the creation of smaller and more compact electronic devices, a critical requirement in modern electronics.

Energy Efficiency: The low power losses associated with silicon substrates result in energy-efficient electronic systems, making them environmentally friendly and cost-effective.

5. Challenges and Limitations

Despite their numerous advantages, Silicon PCBs come with their set of challenges and limitations. These include:

Cost: The manufacturing process of Silicon PCBs is complex and requires specialized equipment. This makes them more expensive than traditional PCBs.

Thermal Stress: Silicon PCBs can be susceptible to thermal stress, which can impact reliability. Proper design and thermal management solutions are required to mitigate this.

Reliability: Ensuring the long-term reliability of Silicon PCBs is a key concern. Factors like material degradation and mechanical stresses need to be addressed.

To overcome these challenges, ongoing research and development efforts are focused on improving the reliability of Silicon PCBs and reducing manufacturing costs.

6. Future Trends and Innovations

The field of Silicon PCBs is constantly evolving, and several trends and innovations are shaping its future. Some of the key trends include:

Advanced Materials: The exploration of new materials and composites to enhance the properties of Silicon PCBs and reduce costs.

Integration of Additional Functions: Silicon PCBs are increasingly being designed to incorporate additional functions, such as sensors or passive components, to further streamline electronic systems.

Enhanced Miniaturization: Continued efforts to push the boundaries of miniaturization, enabling even smaller and more powerful devices.

Increased Use in Automotive Electronics: The automotive industry is embracing Silicon PCBs to support advanced driver assistance systems, electric vehicles, and other innovations.

The future of Silicon PCBs promises exciting developments that will further drive the progress of modern electronics.

7. Conclusion

In the dynamic world of electronics, Silicon PCBs are a pivotal technology that empowers innovation and performance. They are transforming the way we design and manufacture electronic systems, offering a path to faster, smaller, and more powerful devices. The advantages of Silicon PCBs in terms of performance, thermal management, and miniaturization are compelling, even though they come with certain challenges.

As ongoing research and development efforts address these challenges, we can expect Silicon PCBs to become an increasingly integral part of the electronics industry. Their role in advancing semiconductor technology and enabling the creation of groundbreaking electronic devices is undeniable. Silicon PCBs are not just a part of our future; they are driving it.

With their unique combination of electrical efficiency, thermal conductivity, and miniaturization capabilities, Silicon PCBs are poised to continue their journey as a cornerstone of the electronics industry. They represent a powerful tool in the hands of innovators, engineers, and designers, enabling the creation of the next generation of electronic wonders.

HOME

HOME