Why thick film ceramic PCB is good for oil level sensor in automotive industry?

High-performance and high-precision oil-level sensors are critical in the automotive industry to ensure safety and reliability. Traditional oil level sensors are often made of metal materials, which have many disadvantages such as susceptibility to corrosion, wear and tear, and errors or failures. To overcome these limitations, a new composite material, thick-film ceramic PCB, have been widely used in the manufacturing of automotive oil level sensors due to their high strength, hardness, wear resistance, and compressive strength.

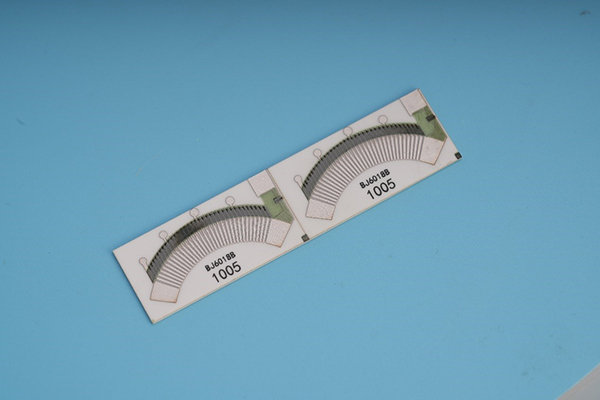

Thick-film ceramic PCB are a new type of composite material made of ceramic and metal materials (Normally it is Au or AgPd), which are processed by a special thick-film technology. The thick-film technology enables the formation of a metal layer on a ceramic substrate (ceramic substrate can be 96%Al2O3 and AlN), providing a strong and stable structure. This structure has high strength, excellent wear resistance, and corrosion resistance, making it ideal for manufacturing oil-level sensors.

The working principle of the thick-film ceramic PCB oil level sensor is based on the excellent piezoelectric properties of the material. Piezoelectricity refers to the property of certain materials to produce an electric charge when a mechanical force is applied. Under mechanical stress, the thick-film ceramic PCB can produce a piezoelectric effect, which separates electrical charges. Utilizing this characteristic, the thick-film ceramic PCB oil level sensor can convert changes in oil level into electrical signals, thereby achieving oil level measurement.

The thick-film ceramic PCB oil level sensor has many advantages.

Firstly, it has a fast response time, enabling real-time monitoring of oil level changes and ensuring that drivers can promptly know the vehicle's oil level status.

Secondly, because thick-film ceramic PCB have high precision and high reliability, the sensor can accurately measure oil level height with a small margin of error.

Additionally, thick-film ceramic PCB have excellent corrosion resistance and wear resistance, enabling the sensor to work stably for an extended period of time in high-temperature and high-pressure environments inside the engine, thus extending the sensor's lifespan.

Moreover, thick-film ceramic PCB have many advantages over traditional metal materials. Metal materials are often susceptible to corrosion, wear and tear, and errors or failures due to exposure to extreme environments such as high temperatures, high pressure, and acid and alkali corrosion. On the other hand, thick-film ceramic PCB have high hardness, wear resistance, and compressive strength, enabling the sensor to withstand harsh environments and perform reliably for an extended period of time. As a result, thick-film ceramic PCB oil-level sensors are increasingly replacing traditional oil-level sensors made of metal materials.

In conclusion, thick-film ceramic PCB, as a new composite material, has high comprehensive performance and is widely used in the manufacturing of automotive oil-level sensors. They not only have high precision and high reliability but also can withstand extreme environments, making them an ideal material for manufacturing high-performance oil-level sensors. The thick-film ceramic PCB oil level sensor, based on the piezoelectric effect, can quickly and accurately measure the oil level height with high sensitivity and stability. With the increasing demand for high-performance and high-precision oil-level sensors, thick-film ceramic PCB oil-level sensors are expected to play an important role in the automotive industry.

HOME

HOME