Do you know how many types for ceramic PCB

In the dynamic realm of electronic engineering, the choice of materials plays a pivotal role in shaping the performance and reliability of components. Ceramic Printed Circuit Boards (PCBs) have gained prominence for their unique properties, making them indispensable in various applications. This article delves into the details of different types of ceramic PCBs, unraveling their specific properties and applications, from high thermal conductivity to mechanical strength.

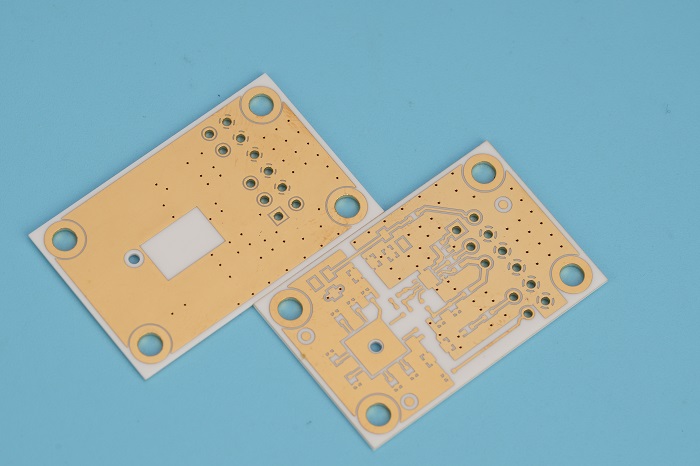

Aluminum Oxide (Al2O3):

Properties:

High Thermal Conductivity: Aluminum oxide stands out for its impressive thermal conductivity. This property makes it an ideal choice for applications requiring efficient heat dissipation.

Good Electrical Insulation: Despite its thermal prowess, aluminum oxide maintains good electrical insulation properties, preventing unwanted electrical interactions.

Applications:

LED Modules and Lighting: The high thermal conductivity of aluminum oxide makes it well-suited for LED modules, ensuring optimal performance and longevity.

Power Electronics: Aluminum oxide is utilized in power electronics applications where effective heat dissipation is crucial for maintaining performance.

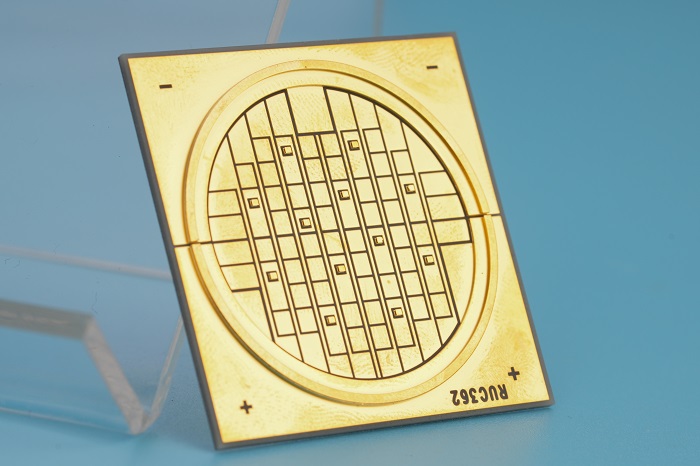

Aluminum Nitride (AlN):

Properties:

Excellent Thermal Conductivity: Aluminum nitride boasts exceptional thermal conductivity, rivaling that of aluminum oxide. This property ensures efficient heat management in demanding applications.

Low Thermal Expansion: With low thermal expansion, AlN remains stable across a range of temperatures, making it suitable for applications with varying heat conditions.

Applications:

High-Power Electronics: Aluminum nitride is a preferred choice in high-power electronic applications, such as IGBT modules, where both thermal performance and electrical insulation are critical.

Microwave and RF Applications: The low dielectric constant of AlN makes it ideal for applications in the microwave and RF frequency range.

Beryllium Oxide (BeO):

Properties:

Extremely High Thermal Conductivity: Beryllium oxide takes the crown for its exceptionally high thermal conductivity, surpassing many other ceramics.

Good Electrical Insulator: Despite its thermal prowess, BeO maintains good electrical insulation properties.

Applications:

High-Performance RF and Microwave: The outstanding thermal conductivity of BeO is harnessed in high-performance RF and microwave applications, ensuring reliable and efficient operation.

Aerospace Electronics: The rugged nature of BeO makes it suitable for demanding aerospace environments where both thermal performance and reliability are paramount.

Silicon Nitride (Si3N4):

Properties:

High Thermal Shock Resistance: Silicon nitride exhibits high thermal shock resistance, making it resilient in applications with rapid temperature changes.

Good Mechanical Strength: Si3N4 possesses robust mechanical strength, contributing to its durability.

Applications:

Automotive Electronics: Silicon nitride finds applications in automotive electronics, particularly in engine components, where it withstands temperature variations and mechanical stress.

High-Temperature Environments: Its resistance to thermal shock makes it suitable for applications in environments with rapid temperature fluctuations.

Zirconium Dioxide (ZrO2):

Properties:

Good Thermal Stability: Zirconium dioxide maintains good thermal stability, providing reliability in high-temperature settings.

High Mechanical Strength: ZrO2 exhibits high mechanical strength, enhancing its durability.

Applications:

Aerospace Applications: Zirconium dioxide is employed in aerospace applications where both thermal stability and mechanical strength are crucial for long-term performance.

Harsh Environment Electronics: Its resilience makes it suitable for electronic components exposed to harsh environmental conditions.

Titanate Ceramics:

Properties:

Good Thermal and Electrical Properties: Titanate ceramics strike a balance between thermal and electrical properties, offering versatility.

Applications:

Multilayer Ceramic Capacitors (MLCCs): Titanate ceramics are commonly used in MLCCs, contributing to their electrical performance and reliability.

General-Purpose Electronic Components: The balanced properties make titanate ceramics suitable for various electronic components where both thermal and electrical considerations come into play.

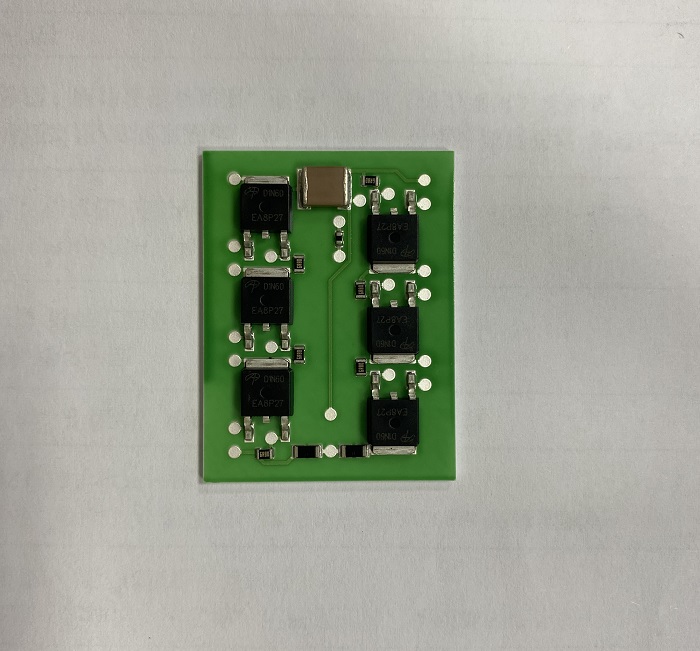

Hybrid Ceramic PCBs:

Properties:

Tailored Solutions: Hybrid ceramic PCBs combine different ceramic materials to achieve specific and tailored properties based on the application requirements.

Applications:

Diverse Applications: Hybrid ceramic PCBs find applications in various industries and electronic devices where a customized approach is necessary.

Customized Designs: Engineers leverage hybrid designs to create customized solutions that balance thermal conductivity, electrical insulation, and mechanical strength.

The world of ceramic PCBs is diverse, offering a spectrum of materials tailored to meet the stringent demands of modern electronics. From the high thermal conductivity of aluminum oxide to the extreme thermal shock resistance of silicon nitride, each ceramic type brings unique properties to the table. As technology advances, the strategic selection of ceramic materials becomes increasingly critical in shaping the performance, reliability, and longevity of electronic components across industries. The journey into the intricate world of ceramic PCBs continues, paving the way for innovations that push the boundaries of electronic engineering.

HOME

HOME