How Does Ceramic PCB Gain a Foothold in Electronic Components?

Ceramic PCB, or ceramic hybrid circuit components, is gradually emerging in global electronic equipment applications and becoming a new standard in the electronics industry. Nowadays, after several years of growth, ceramic PCB has occupied an important position in many cutting-edge technology applications, demonstrating its incomparable advantages.

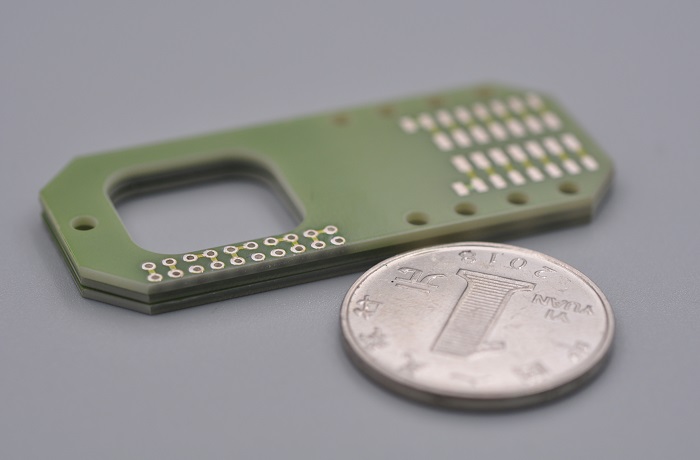

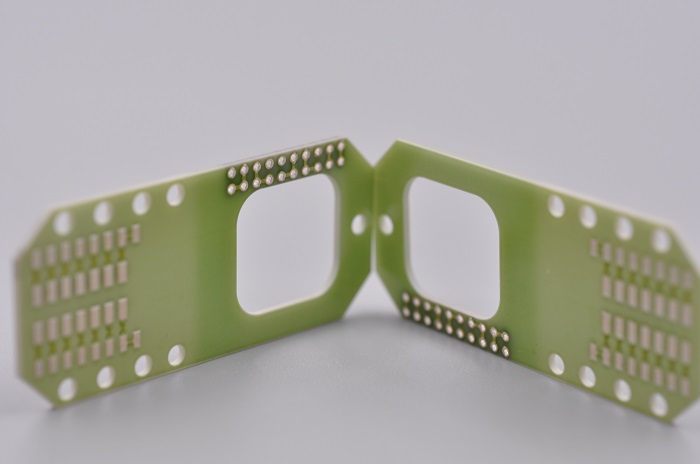

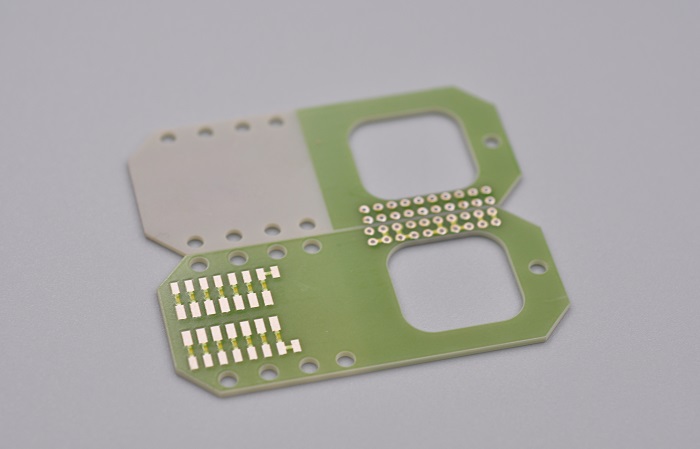

Ceramic PCB is a printed circuit board made of special ceramic materials as the base or substrate. Different from traditional glass fiber or epoxy resin base, ceramic PCB uses high-performance inorganic dielectric materials. These circuit boards are constructed from a ceramic insulating layer with embedded metal components, making them an ideal alternative to many electronic components due to their exceptional durability and reliability. It is worth mentioning that the ceramics mentioned here are not ordinary ceramics in daily life, but specifically refer to industrial-grade high-quality materials, also vividly called "green boards".

The core advantages of ceramic PCB are its high-strength integration and excellent insulation properties. With the rapid development of electronic technology, thousands or even millions of transistors and resistors are integrated into micro silicon chips or integrated circuits. This requires a device that can not only carry complex electronic components, but also effectively isolate the outside world. Interfering substrate and package structures. Ceramic materials have successfully fulfilled this important task with their excellent insulation properties and protective properties, making ceramic PCB unique in many fields.

Especially in industries such as power electronics, hybrid microelectronics, electronic packaging, and multi-chip modules, ceramic PCB are widely favored for their excellent thermal conductivity and air tightness. In application scenarios that require large currents to pass through and have extremely high heat dissipation requirements, such as power generation equipment, ceramic PCB have shown irreplaceable value. In addition, the aerospace and automotive industries also rely heavily on ceramic PCB because they can withstand high temperature, high pressure, corrosion and vibration under extreme conditions and adapt to high power density circuit designs.

In the manufacturing process of ceramic PCB, a wide variety of ceramic materials are used, and the key attributes are their thermal conductivity and coefficient of thermal expansion (CTE). Ceramic materials such as aluminum oxide (Al2O3), aluminum nitride (AlN), beryllium oxide (BeO), silicon carbide (SiC), and boron nitride (BN) are common options when manufacturing ceramic PCB. Compared with ceramic PCB with concentrated materials, alumina ceramic PCB are the most cost-effective.

Alumina has become the most common ceramic material due to its excellent cost performance and wide applicability. Aluminum oxide, also known as aluminum trioxide, is an inorganic compound that is usually white in color and may be slightly pink to brown depending on its purity. As an excellent electrical insulator, aluminum oxide has a high electrical resistivity, with purity typically ranging from 94% to 99%. Because of its good thermal stability and corrosion resistance, high strength and high dielectric strength, as well as the airtight sealing performance formed under certain conditions, alumina ceramic PCB has excellent thermal conductivity, making it an excellent choice for thermal insulation The material of choice for all types of applications beyond the highest requirements.

To sum up, Best Technology ceramic PCB has become a supplier in the modern electronics industry with its unique advantages and wide application, accompanied by continuous innovation in scientific research and technology. Its industrial technology will surely extend a broader application space in the future, bringing greater convenience and possibility to the development of electronic products in all walks of life.

If you are looking for ceramic PCB manufacturers and suppliers, you should fully consider your own needs and application scenarios, and choose the most suitable type of ceramic material in order to achieve the best technical and economic benefits.

HOME

HOME