How does ceramic PCB get a wide application in automobiles?

Introduction

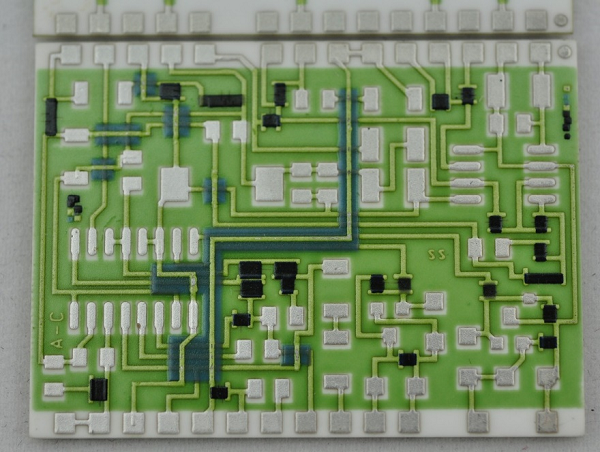

With the intelligent and electrical development of automobiles, ceramic PCB has been widely seen in the automobile industry. As a ceramic PCB supplier with 17 years of experience, we would like to have a deep talking about ceramic PCB's application in the automobile industry with you.

New chapter of ceramic PCB in automobile

With continued innovation and development in automobiles, the requirement for new technology for automobiles is higher and higher. Such as increasingly stringent requirements for automotive electronics reliability, stability, and performance. As a result, the ceramic PCB is the key and ideal choice for the new technology due to its special characteristic of high-temperature resistance, corrosion resistance, and electrical properties. As a specialist in ceramic PCB, we deeply know how the advantages of ceramic PCB meet the high requirements of high performance and high reliability.

The advantage of ceramic PCB

High-temperature stability and corrosion resistance

In automotive electronic systems, high-temperature environments are common, and ceramic PCBs stand out for their excellent high-temperature stability. Compared with traditional PCBs, ceramic PCBs can maintain stable electrical performance under extreme temperature conditions, ensuring the normal working of electronic components in high-temperature environments. At the same time, its excellent corrosion resistance enables it to cope with complex and changeable automotive working environments and ensure long-term reliable operation of the system.

Excellent electrical performance

Ceramic PCBs exhibit excellent performance in electrical performance. Its high insulation performance minimizes interference between electronic components, helping to improve the system's anti-interference ability. In addition, ceramic substrates have excellent thermal conductivity, which helps dissipate heat and ensure that electronic components remain stable under high-load working conditions.

Advantages of dimensional accuracy and manufacturing process

The ceramic PCB manufacturing process has high dimensional accuracy and a flexible manufacturing process, which can meet the demand for miniaturized and lightweight modern automotive electronic components. The advanced processes used in its manufacturing process, such as laser cutting technology, ensure the dimensional accuracy and stability of the PCB and improve the integration and performance of electronic components.

By fully utilizing these advantages of ceramic PCBs, our company is committed to providing more reliable and stable solutions for automotive electronic systems. In the following content, we will deeply into the successful cases of ceramic PCB technology in specific applications, as well as our company's efforts to continuously improve manufacturing processes and product performance.

The specific application scenarios in the field of automotive electronics

Ceramic PCB application in engine control unit (ECU)

The engine control unit (ECU) is the core of the automobile engine management system and is responsible for monitoring and controlling the working of the engine. In this high-temperature, high-pressure environment, ceramic PCB technology has been widely used. Its high-temperature stability ensures the reliability of the ECU under extreme working conditions, while the corrosion resistance of the ceramic PCB enables it to adapt to harsh climate conditions in the engine compartment for a long time. Our company's technological experience in this ceramic PCB field provides key support for improving engine system performance and optimizing fuel efficiency.

Ceramic Technology in Advanced Driver Assistance Systems (ADAS)

With the popularity of advanced driver assistance systems (ADAS), cars have increasingly higher requirements for perception and response. The application of ceramic PCB technology in ADAS, especially the use of ceramic PCBs in sensor and radar systems, can provide excellent electrical performance and stability. This lays a solid foundation for cars to achieve higher levels of autonomous driving functions. The technological innovation in the ADAS field has promoted the transformation of automotive electronic systems from passively monitoring to actively intervening.

Innovation in electric vehicle battery management systems (BMS)

The electric vehicle battery management system (BMS) is crucial to the safety, stability, and life of the battery. Ceramic PCB technology plays an important role in BMS. Its advantages of high insulation, high-temperature resistance, and dimensional accuracy ensure the stable operation of battery components. The continuous upgrade of BMS's ceramic PCB technology provides solid support for the reliability and performance of electric vehicles.

Future Outlook

A. Potential development direction of ceramic PCB in automotive electronics

With the rapid development of the automotive electronics industry, the application prospects of ceramic PCB as a key technology will be broader. In the future, we foresee the following development directions:

Lightweight design: As automobile design develops in the direction of lightweight, the lightweight properties of ceramic PCBs will become an important advantage in future designs and are expected to play a key role in improving vehicle fuel efficiency and electric vehicle cruising range.

Higher temperature stability: As the operating temperature of automobile engines and electronic systems increases, ceramic PCBs will continue to pursue higher temperature stability to meet the reliability needs of future automotive electronic systems in extreme environments.

B. Our company's future development strategy and plans

Our company will continue to be committed to the research development and innovation of ceramic PCB technology to meet the changing market and the continuous upgrading needs of customers. The main directions for future development include:

Technology upgrade: Continue to invest in research and development to improve the technical level of ceramic PCB and promote its continuous innovation in the field of automotive electronics to meet the higher performance and reliability requirements of future automotive electronic systems.

International cooperation: Seek broader international cooperation, strengthen cooperation with automobile manufacturers, technology companies, etc., and jointly promote the development of automotive electronics technology.

Conclusion

In this article, we have an in-depth exploration of the innovation and application of ceramics in the field of automotive electronics. Ceramic PCBs have demonstrated their outstanding performance in different application scenarios, bringing a new chapter to the automotive electronics industry. As a leading company in the ceramic PCB industry, we deeply feel the responsibility and mission to promote the development of the industry. We insist on customer satisfaction as the center, adhere to sustainable development, continue to invest in research and development, and continue to lead the technological innovation of ceramic PCBs. We are confident in the future of ceramic PCBs playing an increasingly important role in the automotive electronics industry and look forward to providing reliable solutions for your ceramic PCB applications in automotive electronics.

HOME

HOME