How to Choose A Suitable Ceramic PCB For Your Project

At Best Technology, we understand the importance of selecting the right ceramic PCB (Printed Circuit Board) for your electronic applications. Whether you are designing high-frequency devices, power electronics, or any other circuit that requires excellent thermal management, choosing the appropriate ceramic PCB is crucial to ensure optimal performance and reliability. In this comprehensive guide, we will provide you with detailed insights and expert recommendations to help you make an informed decision.

Understanding the importance of ceramic PCB

Different with FR4 PCB, ceramic substrate is the base material of the ceramic circuit board, and plate metal or print resistance on the top layer according to the specific demands. Ceramic PCBs offer several advantages over traditional PCB materials, making them ideal for various applications.

-

Thermal Management

Ceramic PCBs have exceptional thermal conductivity, enabling efficient heat dissipation from critical components. This characteristic is particularly valuable in high-power applications or devices operating in extreme temperature conditions.

-

High-Frequency Performance

With their low dielectric loss and high insulation resistance, ceramic PCBs exhibit excellent signal integrity and low electrical losses at high frequencies. These properties make them ideal for RF (Radio Frequency) and microwave applications.

-

Mechanical Strength

Ceramic PCBs possess remarkable mechanical strength and stability, ensuring reliable performance even in harsh environments or applications subject to mechanical stress.

Now, let's delve into the key considerations when choosing a ceramic PCB.

1. Material Selection

When selecting a ceramic PCB, the choice of material is crucial. Various ceramics, such as Alumina (Al2O3), Aluminum Nitride (AlN), and Silicon Nitride (Si3N4), are commonly used in PCB manufacturing. Each material has its unique characteristics and suitability for specific applications.

- Alumina (Al2O3)

Alumina is widely used for its excellent electrical insulation and thermal conductivity properties. It is suitable for general-purpose applications and offers a cost-effective solution.

- Aluminum Nitride (AlN)

Aluminum Nitride exhibits exceptional thermal conductivity, making it ideal for high-power applications that demand efficient heat dissipation. Compared with Al2O3, the thermal conductivity of AlN can be 170-230w/mk, while Al2O3 is 15-35w/mk.

- Silicon Nitride (Si3N4)

Silicon Nitride combines good electrical insulation with high mechanical strength, making it suitable for applications requiring both thermal management and reliability.

Consider your specific application requirements and consult with our experts to determine the most suitable ceramic material for your PCB.

2. Layer Configuration and Design

The layer configuration of a ceramic PCB plays a vital role in its functionality and performance. You can consider the following aspects when designing the layer stack:

- Signal and Power Integrity

Separate the signal and power planes to minimize interference and ensure optimal signal integrity. Proper ground plane placement is critical for effective noise reduction and impedance control.

- RF/Microwave Applications

For high-frequency applications, it is essential to incorporate controlled impedance structures and transmission lines to maintain signal integrity.

- Component Placement

Carefully plan the placement of components to minimize signal distortions and optimize thermal management. Consider the proximity of heat-generating components to avoid hotspots.

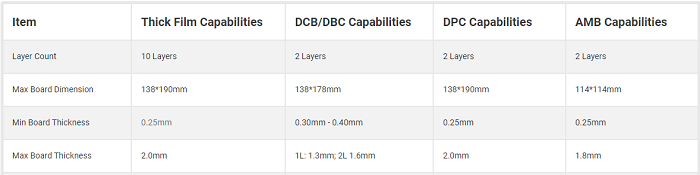

Here is a layer configuration for different ceramic PCBs.

Our experienced design team can assist you in creating a customized layer configuration that meets your specific requirements.

3. Thermal Management Considerations

Ceramic PCBs are renowned for their exceptional thermal conductivity, but additional measures can further enhance their thermal management capabilities:

- Thermal Vias

Designing integrate thermal vias to improve heat transfer between different layers of the PCB. These vias provide a direct thermal path, enhancing heat dissipation efficiency.

- Heat Sinks

For applications with stringent thermal requirements, consider incorporating heat sinks or thermal pads to maximize heat dissipation.

- Optimal Copper Distribution

Ensure proper distribution of copper traces and planes to facilitate efficient heat transfer. Thicker copper traces can enhance heat dissipation capabilities.

Our engineering team can provide valuable insights and simulations to optimize the thermal management of your ceramic PCB design.

4. Manufacturing Considerations - Best Technology

When selecting a ceramic PCB manufacturer, consider the following factors:

Experience and Expertise: Partner with a manufacturer who has a proven track record in producing high-quality ceramic PCBs and can offer technical support throughout the design and manufacturing process.

Quality Control: Ensure that the manufacturer follows stringent quality control procedures and adheres to industry standards to deliver reliable and consistent products.

Prototyping and Production Capabilities: Verify that the manufacturer can cater to your prototyping and production volume requirements. Prompt delivery and scalability are crucial for successful project execution.

Choosing the right ceramic PCB is a critical decision that can significantly impact the performance and reliability of your electronic applications. By considering the material selection, layer configuration, thermal management, and manufacturing considerations outlined in this guide, you can make an informed choice that meets your specific requirements.

At Best Technology, we are committed to delivering top-notch ceramic PCB solutions tailored to your unique needs. With our expertise in ceramic PCB design and manufacturing, we ensure that you receive a product of the highest quality, enabling your electronic applications to excel in performance and durability. Contact us today to discuss your ceramic PCB requirements and let our team of experts guide you in selecting the optimal solution.

HOME

HOME