What is the Role of Ceramic Printed Circuit Boards in Advancing IGBT Technology?

I. Introduction

With the continuous progress of technology, the demand for high-performance and highly stable electronic materials in the field of power electronics has been steadily increasing. The ceramic PCB industry has seen significant development in this sector. Over the years, our company has been dedicated to the research and innovation of ceramic PCB technology, accumulating 17 years of experience in the field.

In power electronic devices, the Insulated Gate Bipolar Transistor (IGBT) serves as a crucial power-switching device widely used in power inverters and converters. Its application in power inverters and converters makes it a core component in controlling and converting electrical energy. Therefore, the performance and reliability of IGBT directly affect the stable operation of the entire power electronic system. To further enhance the performance of IGBT, ceramic printed circuit boards have emerged as a novel material, bringing a series of breakthroughs to the IGBT field.

II. Overview of IGBT Technology

The IGBT, or Insulated Gate Bipolar Transistor, is a power-switching device that integrates Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) and bipolar transistor functionalities. Its fundamental operation involves controlling the current flow through the device by manipulating the gate voltage. In summary, IGBT combines the high input impedance of MOSFET and the current-carrying capacity of bipolar transistors, making it perform exceptionally well in high-power applications.

IGBT technology finds extensive applications, especially in power inverters and converters. The conversion and inversion of current are crucial for regulating the flow of electrical energy in power systems. As a high-performance power-switching device, IGBT efficiently controls current and achieves effective energy conversion. Its applications in areas such as electric vehicles and renewable energy generation systems continue to expand.

With technological advancements, the performance requirements for IGBT technology are increasing. The design of new IGBT devices not only improves performance but also reduces power consumption, enhancing system reliability. Innovations include higher operating frequencies, lower on-state voltage drops, and increased current tolerance, providing more flexible options for the design of power electronic devices. In this evolving technological environment, ceramic printed circuit boards play an increasingly important role as a key component in IGBT applications. This article delves into the characteristics of ceramic PCBs and their advantages in IGBT applications.

III. Characteristics of Ceramic Printed Circuit Boards

A. Overview of the Advantages of Ceramic PCBs

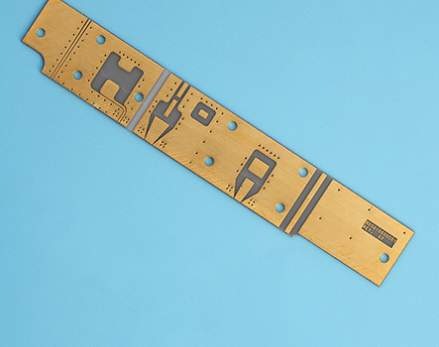

Ceramic PCBs offer unique advantages in the IGBT field compared to traditional materials. Firstly, ceramic materials exhibit excellent thermal conductivity and insulation properties, making ceramic printed circuit boards perform exceptionally well in high-power devices. Secondly, the chemical stability and corrosion resistance of ceramic materials contribute to the longevity of circuit boards. Additionally, ceramic PCBs can meet the requirements of compact designs, providing higher integration and reducing the volume and weight of IGBT.

B. Stability and Reliability in High-Temperature, High-Frequency, and High-Voltage Environments

One major advantage of ceramic printed circuit boards in IGBT applications is their stability and reliability in extreme environments. Power electronic devices often operate in high-temperature, high-frequency, and high-voltage conditions, and ceramic PCBs can maintain stability under these extreme conditions. Their outstanding high-temperature performance makes ceramic printed circuit boards an ideal choice in power systems, especially in applications requiring high heat dissipation and resistance to high temperatures, such as power inverters.

C. Comparison with Traditional Materials

Compared to traditional substrate materials like FR-4 (fiberglass-reinforced epoxy resin), ceramic printed circuit boards demonstrate superior performance in high-temperature and high-frequency environments. FR-4 may lose stability at high temperatures, whereas ceramic PCBs can operate over a broader temperature range. Moreover, ceramic materials have better insulation properties, offering improved resistance to electromagnetic interference and enhancing the system's immunity to interference.

IV. Advantages of Ceramic Printed Circuit Boards in IGBT Applications

A. Improved Heat Dissipation for Enhanced Stability of Electronic Devices

One notable advantage of ceramic printed circuit boards in IGBT applications is their excellent heat dissipation performance. In high-power applications, IGBT devices generate heat that needs efficient dissipation to maintain normal operating temperatures. The high thermal conductivity of ceramic PCBs enables more effective conduction and dispersion of heat, thereby improving the overall system's heat dissipation performance. This not only helps reduce system temperature but also enhances the stability and reliability of electronic devices, extending the lifespan of the equipment.

B. Value of High-Temperature Resistance and Pressure Resistance in Power Electronic Devices

In power electronic devices, IGBTs often face working environments with high temperatures and pressures. The high-temperature resistance and pressure resistance characteristics of ceramic printed circuit boards enable them to operate stably under these extreme conditions, ensuring the normal functioning of the system. Their superior performance makes ceramic PCBs an ideal choice for circuit board materials in high-power electronic devices such as power inverters and converters, providing a more reliable foundation for equipment.

C. Suppression of Electromagnetic Interference by Ceramic Materials

Electromagnetic interference is a significant challenge for electronic devices, especially in high-power and high-frequency applications. Ceramic materials, with their excellent insulation properties, can effectively suppress the generation and propagation of electromagnetic interference. By adopting ceramic printed circuit boards, the level of internal electromagnetic interference in the system can be reduced, enhancing the stability and interference resistance capability of the entire power electronic system.

Considering these advantages, ceramic printed circuit boards exhibit outstanding performance in IGBT applications, bringing significant technological advancements to the IGBT field. In practical applications, these advantages directly impact the efficiency, reliability, and stability of power systems.

V. Future Development Trends

Ceramic PCB technology holds vast prospects in the IGBT field. With the continuous upgrading of power systems and the increasing demand for high-performance and highly reliable electronic devices, ceramic printed circuit boards, as a key component, will play an increasingly crucial role. In the future, we can anticipate further improvements in the thermal conductivity and high-temperature resistance of ceramic PCBs, adapting better to high-frequency and high-voltage environments. Additionally, integration with other advanced materials and technologies will drive innovative applications of ceramic PCBs in the IGBT field.

The power electronics industry will continue to embrace numerous new trends, such as the widespread adoption of renewable energy, the development of electric transportation, and the promotion of smart grids. These trends provide opportunities for the ceramic PCB industry, especially in applications requiring high power density and high-temperature environments. However, along with opportunities come a series of challenges, including higher performance requirements, stricter standards, and constantly changing market demands. Best Technology Limited needs to maintain keen market insights, flexibly adjust strategies, and better adapt to the dynamic developments in the industry.

To address future challenges and seize opportunities, the company will continue to strengthen innovation in the field of ceramic printed circuit boards. This includes ongoing efforts to enhance the performance of ceramic PCBs, expand their applicability, promote the research and development of new materials and processes to meet evolving market demands. The company will also strengthen collaboration with partners to jointly advance the application and promotion of ceramic PCB technology in the IGBT field. Through continuous innovation, the company aims to maintain a leading position in the industry, providing customers with more competitive solutions.

VI. Conclusion

In summary, ceramic printed circuit boards demonstrate numerous key advantages in IGBT applications. Their outstanding performance in improving heat dissipation, high-temperature resistance, pressure resistance, and electromagnetic interference suppression makes them an ideal choice in power electronic systems. By adopting ceramic PCBs, electronic devices can operate more

HOME

HOME