Why AlN Ceramic Substrate is Suitable for Auto Headlight?

With the continuous increase in LED light source power and the higher integration level of packaging, ceramic substrate plays a vital role in enhancing the stability of LED light sources and significantly improving the reliability of high-power LED light sources.

Background

In recent years, there has been intense competition in the research, development, and application of ceramic materials both domestically and internationally. To meet market demand and dominate the market, automotive manufacturers are focusing on improving design in areas such as lens and housing in automotive headlights. Another aspect is the replacement of lighting fixtures, transitioning from xenon lamps to LED headlights. Therefore, aluminum nitride (AlN) ceramic substrates as the core material for auto headlights, thus becoming the forerunners in verifying AlN ceramic PCBs.

Why AlN Ceramic Substrate Is the Best Option for Auto Headlight?

The working temperature of automotive LED headlights is extremely high, and failure to dissipate heat promptly can accelerate brightness degradation. Therefore, the performance of the LED heat sink becomes crucial. Aluminum nitride ceramic substrates shows a series of advantages such as high thermal conductivity, excellent insulation properties, and thermal expansion technology that is more compatible with the LED chips. They are an excellent choice for high-power headlights. Moreover, aluminum nitride ceramic substrates find applications beyond automotive headlights, including various sensors and high-power modules in smart cars, indicating promising prospects for their usage.

The automotive headlight industry mainly uses three types of substrates: aluminum substrates PCB, AlN substrates, and aluminum oxide (Al2O3) substrates.

1.Aluminum PCB

Aluminum PCB is a type of metal core PCB (MCPCB), it always be used in automotive headlights because it has higher thermal conductivity than normal fiber glass FR4 PCB.

However, when used in automotive headlights, it requires good heat dissipation design for matching, such as adding heat sink or fans heat sinks. Otherwise, the junction temperature will still very high, leading to luminous decay over time, resulting in a rapid decline in headlight brightness. In another way, the design of heat sinks also increase the cost of the aluminum PCB manufacturing, which is much higher compared to DPC ceramic PCBs.

2.Al2O3 Ceramic PCB

It is widely used in LED lights and with lower costs compared to DPC technology, and its thermal conductivity is about 10 times higher than aluminum PCB. In theory, they are sufficient for use as headlight LEDs. However, with the increasing power of automotive needs, automotive companies will try to increase brightness to meet customer’s requirements. But if brightness increases, power will also increase accordingly, Al2O3 ceramic substrate is insufficient to use. Nowadays, the Al2O3 materials most suitable to use in low-power applications such as street lights.

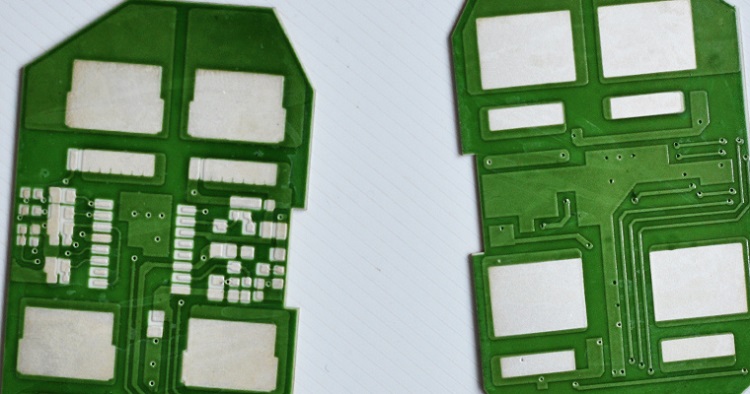

3.AlN Ceramic PCB

AlN ceramic substrate is the most widely used in automotive LED headlights. It has 10 times higher thermal conductivity than aluminum PCB and 100 times higher than Al2O3 material, which is the ideal choice for high-power headlights. In addition, its hardness is much higher than that of Al2O3 as well, solving the problem of fragile ceramic substrates. And the most important thing is AlN ceramic PCB enable to perfectly adapt the previous manufacturing process and saving a lot of expenses for enterprises. In fact, DPC ceramic PCB has widely applications in cars, such as various sensors and high-power modules in smart cars.

Why Select Best Technology as Your Ceramic PCB Supplier?

The future application of DPC ceramic substrates will become increasingly widespread, making ceramic substrates more accessible and expanding into various industry sectors. If you are a designer, and want to use a ceramic PCB in your new project, welcome to contact us. Best Technology is a professional ceramic PCB manufacturer who has over 17years experience. Our manufacturing process is pretty mature than other suppliers, whatever for DPC technology or DBC, thick film, thin film, LTCC or HTCC technology. Choose us, you will enjoy a top-notch quality products and one-stop service.

HOME

HOME