Why ceramic circuit boards are so excellent?

With the continuous advancement of science and technology and the continuous expansion of industrial applications, the performance requirements for electronic components are also increasing day by day, especially in high-temperature environments. In this context, ceramic circuit boards, as a new basic material, have attracted much attention due to their excellent high-temperature performance. This article will delve into the performance of ceramic circuit boards and their application prospects in various fields.

1. High-temperature stability of ceramic circuit boards

Ceramic circuit boards stand out for their outstanding high-temperature stability. In high-temperature environments, many traditional materials may encounter problems such as performance degradation and deformation, while ceramic circuit boards can maintain relatively stable electrical and mechanical properties. Due to the high melting point of ceramic materials, ceramic circuit boards can safely withstand temperatures up to 1000°C, making them ideal for many high-temperature industrial applications such as aerospace, automotive electronics, and energy.

2. Superior thermal conductivity

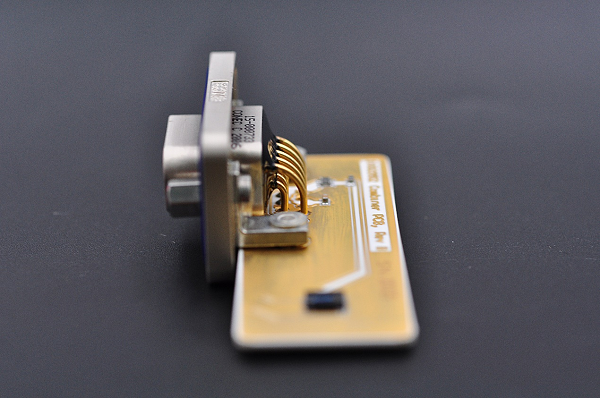

In addition to high-temperature stability, ceramic circuit boards also have excellent thermal conductivity properties. In high-temperature environments, electronic components often generate a large amount of heat, and excellent thermal conductivity helps to quickly conduct heat away to prevent components from overheating and damage. This provides reliable protection for electronic equipment in high-temperature working environments.

3. Advantages of low dielectric loss

Dielectric loss, a critical factor in signal transmission, refers to the energy dissipated as heat when an electromagnetic field interacts with a material. In the case of ceramic circuit boards, the dielectric loss is notably low, signifying that minimal signal energy is lost during transmission. This characteristic is particularly advantageous in applications where high-frequency signals demand optimal stability.

Ceramic circuit boards have the characteristics of low dielectric loss, which means that in high-frequency applications, the loss of signal transmission is relatively small. In fields such as wireless communications and radar systems that require extremely high signal stability, ceramic circuit boards have demonstrated their unique advantages in high-frequency environments.

Ceramic materials are known for their stability across a wide temperature range. The low dielectric loss in ceramic circuit boards contributes to temperature stability, making them suitable for applications where temperature fluctuations are common. This is particularly important in aerospace and automotive applications, where electronic components may be exposed to varying environmental conditions.

4. Application field

The application of ceramic circuit boards in the aerospace field is particularly eye-catching. During the process of reentry into the atmosphere, the spacecraft faces extremely high temperatures and high-speed environments. Traditional materials may not be able to meet the needs of these extreme conditions, but ceramic circuit boards can operate stably to ensure that the aircraft's electronic systems work normally under extreme conditions. In the aerospace field, ceramic circuit boards are used in flight control systems to ensure that these systems work properly under high-speed flight and complex climate conditions.

In other practical applications, ceramic circuit boards have been widely used in various electronic device fields. For example, in the field of automotive electronics, ceramic circuit boards are used in ignition systems and power control systems to improve the reliability and stability of these systems. In addition, ceramic circuit boards are also used in military equipment to improve the anti-interference performance and reliability of these equipment.

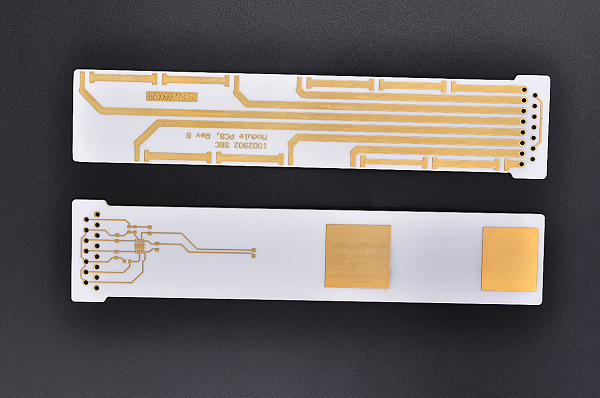

5. Manufacturing process and cost considerations

Although ceramic circuit boards perform well in high-temperature environments, their manufacturing processes are relatively complex and costly. In terms of price, the cost of ceramic substrates depends on many factors, such as the number of layers, aperture size, copper layer thickness, and plate thickness. This requires companies to take into account market demand and cost control when formulating pricing strategies. However, for those applications that require extremely high-temperature performance, the performance advantages of ceramic circuit boards may outweigh their manufacturing costs and become an indispensable choice.

6. Industry trends and prospects

As the demand for high-temperature, high-frequency, high-power, and high reliability of electronic equipment in high-temperature environments continues to increase, such as in new energy vehicles, 5G communications, smart manufacturing, and other fields, these demands will promote technological innovation in ceramic circuit boards. In the future, with the further improvement of manufacturing processes and the gradual reduction of costs, it is expected that ceramic circuit boards will be widely used in more fields, providing reliable support for electronic systems in various high-temperature environments.

Overall, the excellent performance of ceramic circuit boards in high-temperature environments makes them the first choice in many high-tech fields. Its high-temperature stability, thermal conductivity, and low dielectric loss make it perform well under extreme conditions, providing a powerful solution to the high-performance requirements of future electronic equipment.

HOME

HOME