Why Coating with Red Ink Before Ceramic Substrate Circuit Board Drilling Process?

I believe most of engineers or designers who tried to understand the manufacturing process of DPC (Direct Plated Ceramic) ceramic circuit boards may heard of such terminology of coating red ink or red coating before drilling step. Do you know the reason of it? Today, I will explain the reasons and benefits of red coating for you, hope this will help you to make sense.

What is Red Coating Meaning?

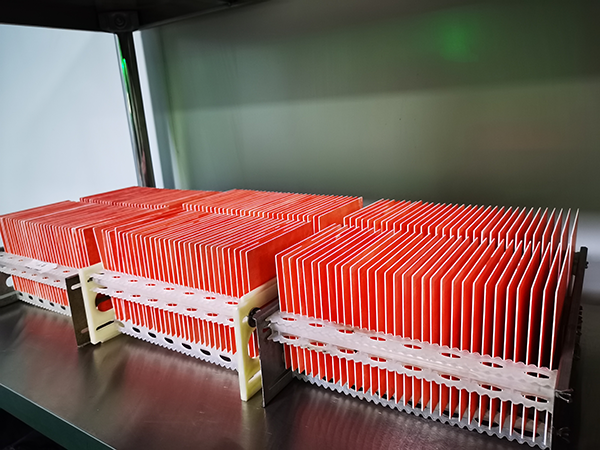

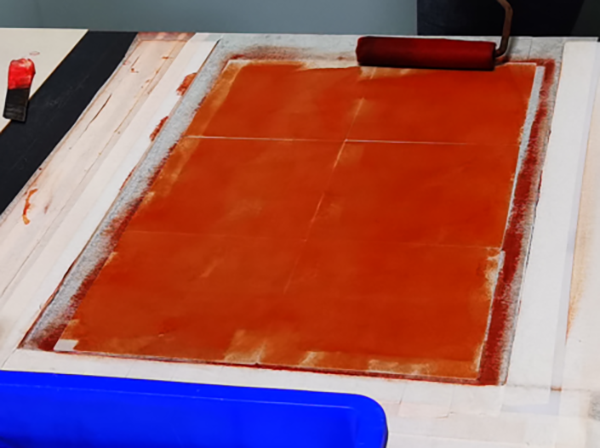

Before we start, let’s know what a red coating is. Red coating, just as its name implies, applying a layer of red ink onto the surface of the ceramic substrate PCB before it undergoes the drilling process. The reasoning behind this practice and the benefits it offers are multifaceted and critical to ensuring the precision and quality of the final product. It is worth noting that the color of ink does not have to be red, other colors also are available, depending on the manufacturer’s preferences and process requirement. But the red is the common color that always be used, that’s why we called it “red coating”.

What is the Purpose of Red Coating?

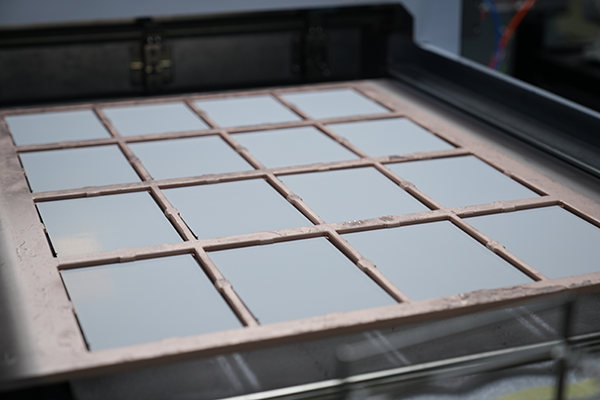

One of the main purposes for applying a red coating is to enhance visibility and contrast during the drilling process. Ceramic substrate PCBs, especially those made from materials like Alumina oxide (Al2O3) or Beryllium oxide (BeO), tend to possess a bright white or light-colored surface. This can create challenges in terms of accurately positioning the drilling equipment and maintaining precision throughout the drilling operation. The application of a red coating introduces a strong visual contrast between the substrate and the coating. This enhanced contrast makes it considerably easier for operators to precisely position and control the drilling equipment, resulting in fewer errors and improved accuracy.

What are Benefits of Red Coating?

Red coating offers some potential benefits in some aspects. Below are some advantages of coating red ink on the substrate.

1. Protection

Though ceramic substrate circuit board have high hardness, they still easy to be chipping, cracking, or even broken during the drilling process. The red coating serves as a protective barrier between the fragile ceramic surface and the drilling equipment. This coating helps absorb some of the impact forces generated during drilling, reducing damage risk to the substrate.

2. Reduced risk of broken

During the drilling process, broke between the drill bit and the ceramic substrate circuit board is inevitable. If substrate be broken, it can lead to wear and degradation of the drill bit over time. The red coating reduces the broken between the drill bit and the substrate, resulting in less wear on the drill bit and an extended tool life. This, in turn, saving some costs by reducing the frequency of tool replacements and maintenance.

3. Debris Management and Contamination Prevention

During the drilling operations, some debris and particles will be generated. That could potentially adhere to the ceramic surface, causing defects or contamination finally. The red coating enables to as a barrier that captures and contains the drilling debris. This prevents debris from adhering to the ceramic surface, thus minimizing the risk of defects and contamination that could impact the performance and reliability of the final product.

4. Improved Yield and Efficiency

By applying red ink into the drilling process of ceramic substrate circuit boards, many potential risks will be decreased, so that manufacturers can improve overall manufacturing efficiency and product quality.

In a word, the usage of coating ceramic substrate circuit boards with red ink or a similar colored coating before the drilling process enable to offer numerous benefits for DPC circuit board production. Hope this post help you better understanding of importance of red coating. If you have other questions about manufacturing process of ceramic PCB, welcome to leave your comments below or contact us at sales@bestpcbs.com, we are happy to solve questions for you.

HOME

HOME