-

What Is the Thinnest Ceramic Material for RF Devices?

For RF devices, the thinnest ceramic material often depends on the substrate type and the specific frequency range. In general, manufacturers of high-frequency ceramics like Alumina (Al₂O₃), Aluminum Nitride (AlN), and Beryllium Oxide (BeO) can provid 2025-10-01 -

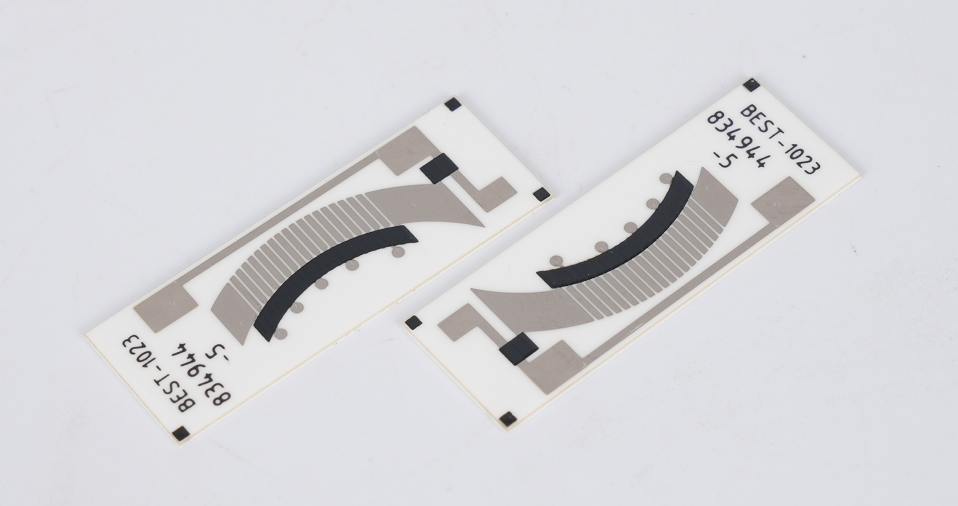

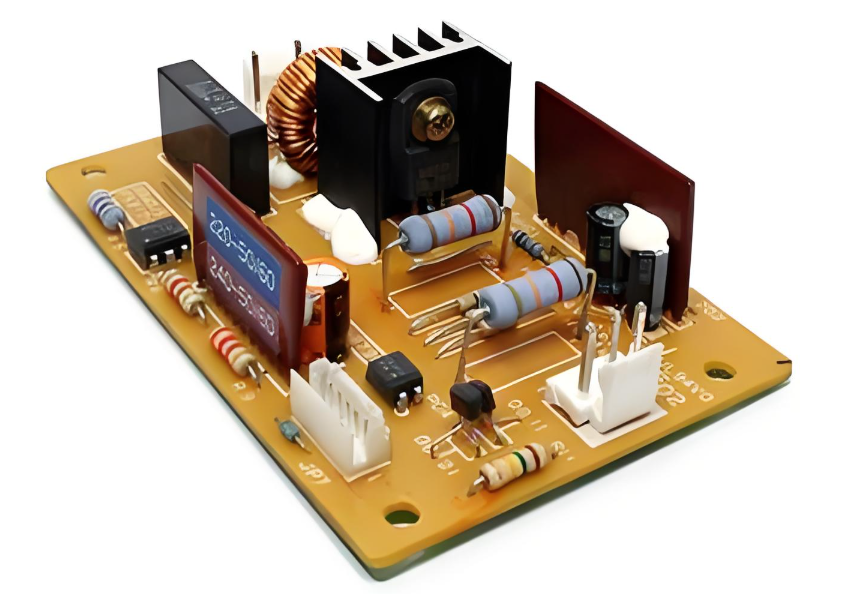

Hybrids Thick Film Ceramic PCB for Fuel Sensors

Hybrid thick film ceramic PCBs have become a cornerstone in automotive sensor technology. Fuel sensors, in particular, require PCBs that can withstand high temperatures, vibration, and chemical exposure. Hybrid designs combine the robustness of ceramic su 2025-09-27 -

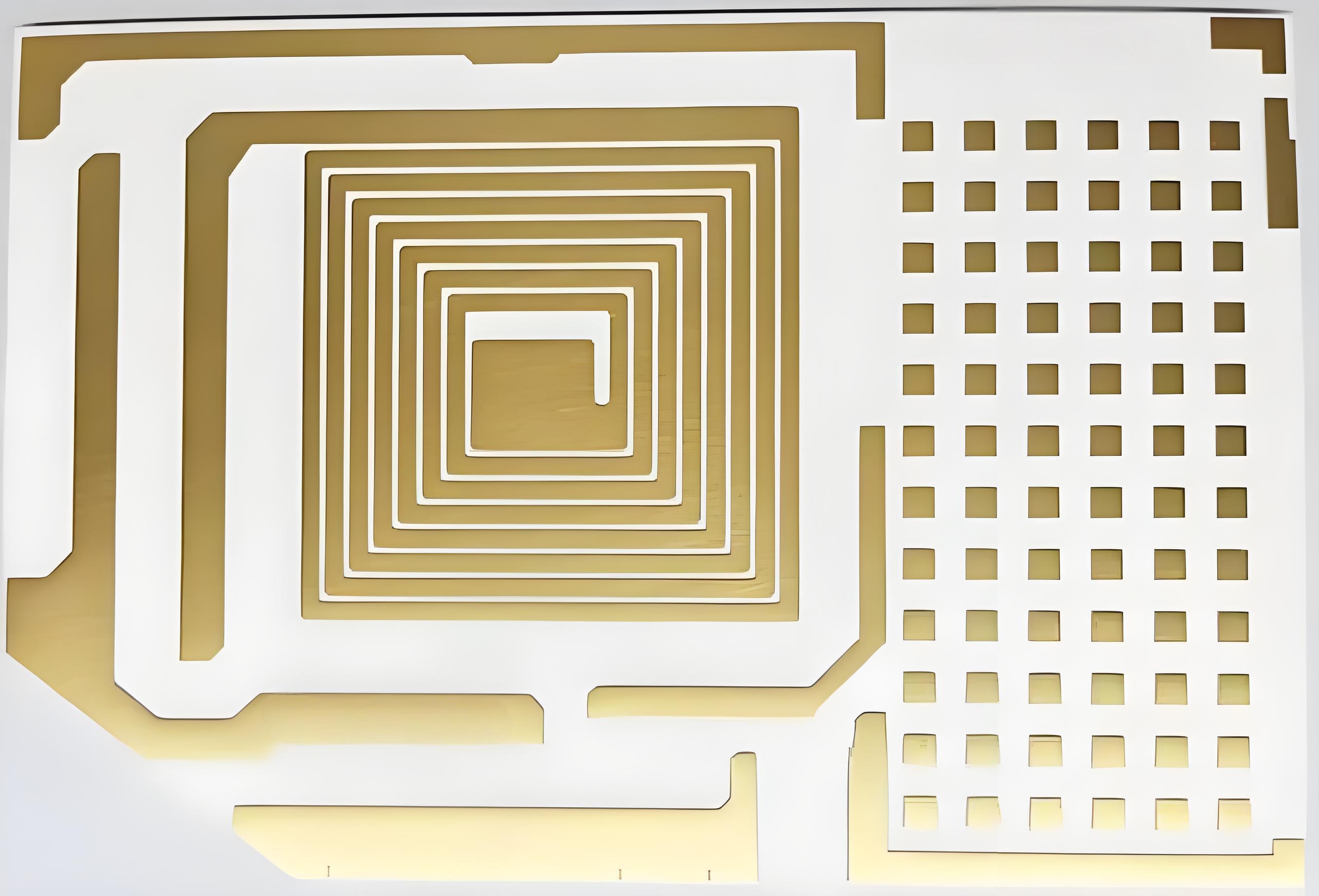

What is Alumina PCB Material? Alumina to Aluminium Process

Alumina PCB is a ceramic-based printed circuit board that relies on aluminum oxide as its substrate. Unlike traditional FR4 boards, alumina PCB material offers outstanding thermal conductivity, excellent mechanical strengt 2025-09-25 -

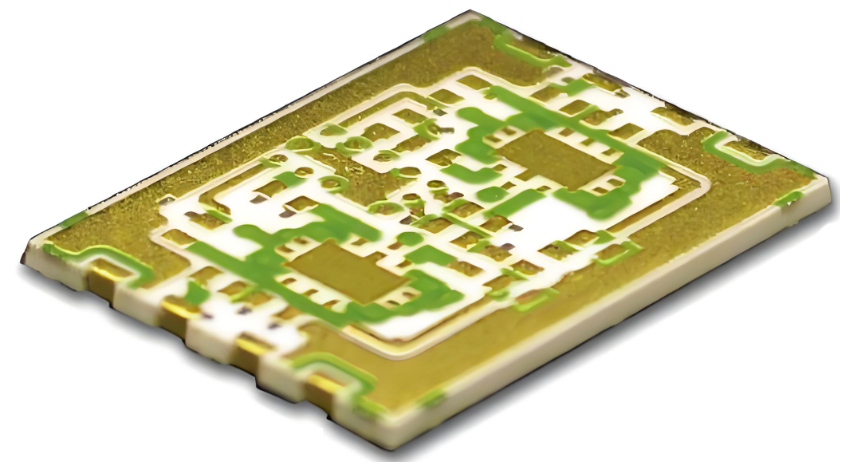

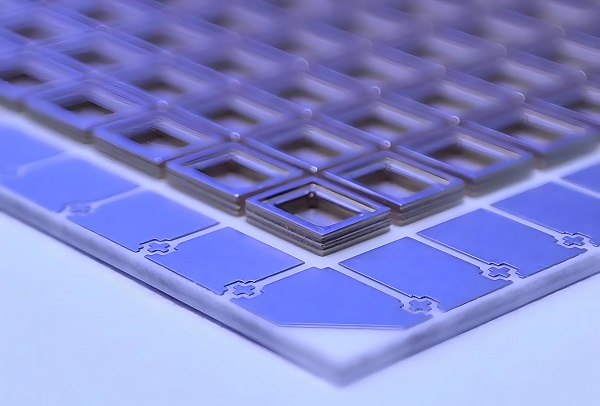

Wire bondable 2-layer Alumina substrates PCB | Bstceramic PCB

As electronic systems evolve toward higher power density, miniaturization, and long-term reliability, traditional FR4 or metal-core PCBs often fail to meet the requirements. Wire bondable 2-layer alumina substrates PCB provides a solution that combines ce 2025-09-22 -

Ceramic PCB in Stage Lighting: Why It is Better Than FR4 PCB?

Ceramic PCB has become a game-changer in stage lighting, offering unmatched performance in heat management, reliability, and durability. In professional lighting systems—whether in theaters, concerts, or live shows—the demand for brighter, mor 2025-09-01 -

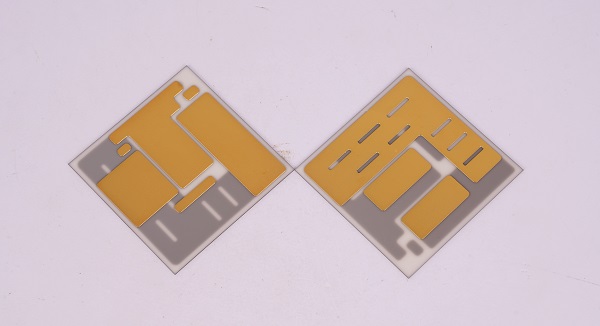

AlN Substrate Ceramic: Everything You Should Know

The AlN substrate has become one of the most important materials in modern electronic manufacturing. As devices continue to get smaller and more powerful, engineers face challenges related to heat buildup and reliability. Traditional materials like FR4 or 2025-09-01 -

What is Aluminium Nitride? Types of Ceramic PCB Material

Aluminium nitride is one of the most valuable ceramic materials used in modern electronics. In PCB manufacturing, it is recognized for its superior thermal conductivity, electrical insulation, and chemical stability. As technology advances, the demand for 2025-08-20 -

What are Different Grades of Alumina? Alumina Ceramic Composition

When it comes to high-performance ceramics, alumina stands out for its wide range of industrial applications. From electronic substrates to wear-resistant parts, alumina is everywhere—but not all alumina is the same. There are different grades of al 2025-08-06 -

7 Commonly Frequently Asked Questions about Ceramic PCBs

1. How much are the dimensions (thickness and maximum size) of different ceramics? Ceramic Type Typical Thickness (mm) Maximum Size (mm) Alumina (Al₂O₃) 0.20 – 2 2025-08-05

HOME

HOME